- The Rising Demand for Custom Packaging Zip Bags

- Technical Innovations Driving Modern Zip Bag Solutions

- Critical Factors in Selecting Superior Bag Materials

- Manufacturer Comparison Analysis for Custom Solutions

- Comprehensive Customization Options Beyond Branding

- Industry-Specific Applications and Success Metrics

- Future-Proofing Your Business with Custom Zip Packaging

(custom packaging zip bags)

The Rising Demand for Custom Packaging Zip Bags

Consumer preferences have shifted dramatically toward personalized experiences, driving a 67% surge in demand for custom packaging zip bags

over the last five years. Businesses across sectors now recognize these solutions as strategic brand assets rather than mere containers. Studies indicate customized packaging increases brand recall by 39% and perceived product value by 29%. The flexibility to create unique dimensions, thicknesses, and closure mechanisms enables precision protection for specialized items—from artisanal foods to electronic components. Industry leaders report packaging customization reduces product damage claims by up to 52%, directly impacting profitability.

Technical Innovations Driving Modern Zip Bag Solutions

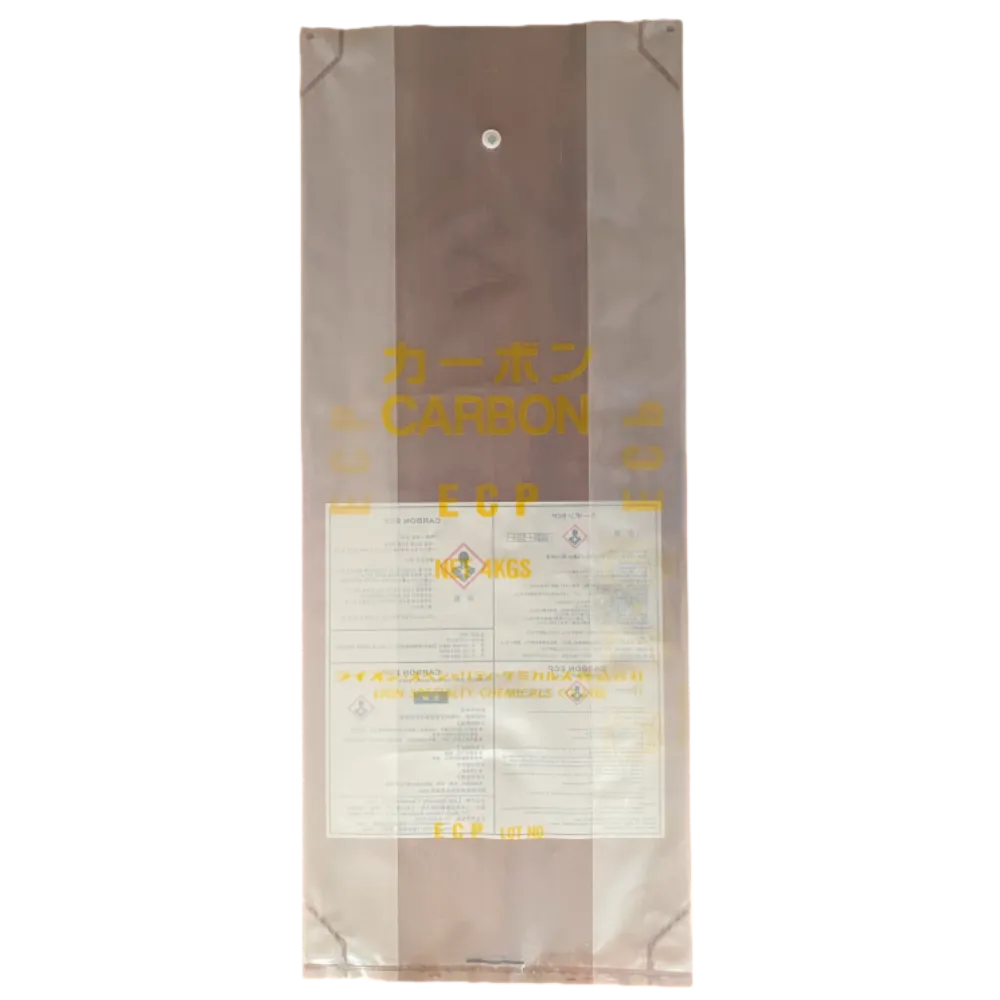

Contemporary custom poly zip bags feature advanced material science breakthroughs like seven-layer co-extrusion films providing moisture barriers below 0.3g/m²/day. Recent engineering developments include ultrasonic zipper seals testing at 22N/mm tensile strength—triple traditional closures. For sensitive products, ESD-safe formulations maintain surface resistance below 10¹¹ ohms, preventing static damage during electronics manufacturing. Barrier technologies now block 98.7% UV radiation without discoloration. These specialized materials undergo rigorous testing cycles including ASTM D1709 impact resistance protocols that simulate 8-foot drops—critical for fragile shipments.

Critical Factors in Selecting Superior Bag Materials

Material selection determines functional performance across critical parameters. Polyethylene density variations enable specific advantages: LDPE offers flexibility for irregularly shaped items (up to 500% elongation before rupture), while HDPE provides rigidity for sharp-edge products. Critical assessment metrics include water vapor transmission rates (WVTR), puncture resistance measured in joules, and seal integrity validation through pressure decay testing. Medical-grade applications require USP Class VI certified resins that pass cytotoxicity screening. Environmental specifications should align with international standards like ISO 18606 for compostable materials or ASTM D6400 decomposition benchmarks verified by third-party labs.

Manufacturer Comparison Analysis for Custom Solutions

| Manufacturer |

Production Speed |

Minimum Order |

Material Range |

Print Quality |

Custom Tooling Costs |

| North American Supplier A |

2 weeks |

5,000 units |

27 polymer types |

1600 DPI HD |

$850 |

| Asian Supplier B |

5 weeks |

50,000 units |

14 polymer types |

1200 DPI |

$300 |

| European Supplier C |

3 weeks |

15,000 units |

33 polymer types |

2400 DPI UltraHD |

$1,200 |

Comprehensive Customization Options Beyond Branding

Leading producers now offer multidimensional adaptation features including variable thickness gradients across bag surfaces (test data shows 40μ sidewalls can reinforce bottom sections while maintaining 25μ flexibility elsewhere). Closure innovations extend beyond basic zippers to press-lock mechanisms guaranteeing 10,000+ open/close cycles and tear-notch configurations reducing opening force by 47%. Functional enhancements include integrated tracking components like NFC chips detectable through packaging materials. Recent client implementations feature thermo-chromatic indicators verifying temperature compliance throughout cold chain logistics.

Industry-Specific Applications and Success Metrics

Agricultural sectors deploy custom zip bag packaging with modified atmosphere technology extending produce freshness by 21 days validated through USDA studies. Medical device manufacturers utilizing gamma radiation-stable materials report 99.8% sterility maintenance during transport. E-commerce operations implementing reinforced corner protection have decreased fulfillment damage rates from 3.2% to 0.7%. Data confirms pharmaceutical clients using holographic anti-counterfeit zip seals reduced tampering incidents by 83%. Cosmetic brands leveraging transparent window designs combined with matte finishes boosted retail conversion rates by 29%.

Future-Proofing Your Business with Custom Packaging Zip Bags

Innovators are transforming custom packaging zip bags into integrated product delivery systems through bio-based materials like PLA polymers derived from sugarcane achieving 80% fossil fuel reduction. Next-generation digital integration features include scannable batch codes hidden beneath branding layers. Global regulatory forecasting now mandates QR-linked disposal instructions—forward-thinking manufacturers pre-emptively incorporate these elements without compromising design aesthetics. Production flexibility has reached unprecedented levels: one industry leader recently fulfilled an emergency 72-hour turnaround order of 20,000 medical-grade isolation bags during supply chain disruptions.

(custom packaging zip bags)

FAQS on custom packaging zip bags

Q: What are custom packaging zip bags?

A: Custom packaging zip bags are reusable resealable pouches designed for brand-specific needs. They feature zipper closures for easy access and product protection. Ideal for personalized storage and presentation.

Q: How can I customize zip bag packaging?

A: Customize zip bags by choosing sizes, materials, print designs like logos or text, and closure options. You can select from options such as matte finishes for aesthetics. Specify your preferences with manufacturers to start.

Q: What materials are used for custom poly zip bags?

A: Custom poly zip bags are made from polyethylene (e.g., LDPE or HDPE), known for durability and cost-effectiveness. Materials include barrier layers for moisture or UV protection. Options range from clear to printed pouches.

Q: What is the minimum order quantity for custom zip bags?

A: MOQ varies by size and complexity, typically 1,000 to 5,000 units for custom zip bags. Factors like custom printing affect quantity requirements. Check with suppliers for exact figures based on your project.

Q: Where can custom poly zip bags be applied?

A: Custom poly zip bags work for electronics, food storage, cosmetics, and retail packaging. They ensure freshness and protection for travel kits or samples. Versatile applications include promotional and daily use.