This comprehensive guide explores key aspects of packaging manufacturing and solutions. The content roadmap includes:

- Current packaging market statistics and growth projections

- Cutting-edge manufacturing technologies and capabilities

- Comparative analysis of leading manufacturing specialists

- Material characteristics for different applications

- Implementation of custom branding solutions

- Demonstrated use cases across industries

- Critical partner selection considerations

(custom paper bag manufacturers)

Why Custom Paper Bag Manufacturers Are Essential for Brand Identity

Brand differentiation represents a decisive competitive advantage in today's marketplace. Packaging constitutes an extension of brand identity, particularly within retail environments. Custom paper packaging establishes unique shelf presence while supporting sustainability objectives. Leading manufacturers now deliver capabilities exceeding traditional expectations. Many offer integrated services covering design support, material selection, printing application, and logistics coordination. This comprehensive approach transforms packaging from commodity to strategic brand asset.

Current Packaging Market Trends and Statistics

The global retail packaging market reached $22.3 billion valuation in 2023 with sustainable solutions driving 64% of growth initiatives. Projections indicate 7.8% compound annual growth through 2030. Beyond financial metrics, environmental considerations significantly influence material selection:

- 73% of consumers now consider recyclability before purchase

- Paper accounts for 58% of sustainable packaging solutions

- Flexible packaging requires 35% less energy than rigid alternatives

- Advanced materials enable 22% lighter packaging without reduced durability

Recent innovations incorporate recycled ocean plastics into new packaging streams. Material science developments include biodegradable barrier coatings extending product shelf life while maintaining recyclability. Brands increasingly adopt hybrid packaging architectures combining paper bases with reusable plastic components.

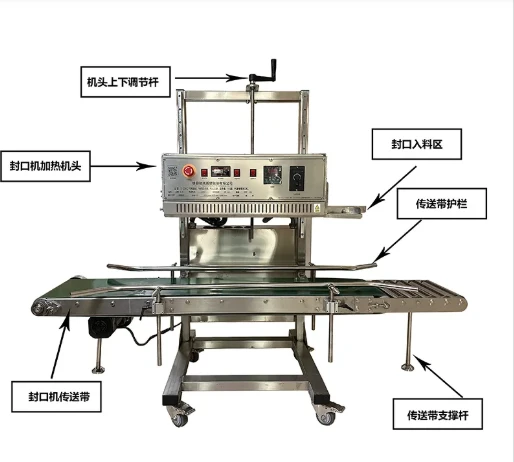

Technological Advantages in Modern Manufacturing

Front-running manufacturers implement integrated manufacturing ecosystems enabling unparalleled production agility. Facilities now utilize AI-driven resource allocation systems that reduce material waste by 18%. Automated optical inspection achieves 99.97% quality consistency across batches. Production lines incorporate features such as:

- Water-based flexographic printing systems exceeding Pantone match standards

- Variable data printing for limited edition promotions

- RFID integration in packaging material substrates

- Augmented reality enabled interactive packaging surfaces

Digital twin capability permits virtual prototyping, eliminating physical sampling waste while accelerating design approvals by 40%. Proprietary texture application systems create distinctive tactile experiences without compromising recyclability. Manufacturing resource planning platforms connect inventory, production, and shipping data into unified operational intelligence dashboards.

Leading Manufacturers Capabilities Comparison

| Specialization |

Material Options |

Printing Capabilities |

Minimum Orders |

Lead Times |

| Premium Paper Packaging |

Kraft, Recycled, Art Paper, FSC Certified |

Full CMYK, Hot Foil Stamping, Embossing |

5,000 units |

3-4 weeks |

| Plastic Packaging |

LDPE, HDPE, RPET, Bioplastic |

Flexo Printing, Screen Printing |

10,000 units |

2-3 weeks |

| Poly Packaging Specialists |

Polypropylene, BoPET, Woven Poly |

Rotogravure, Digital Printing |

15,000 units |

4-5 weeks |

| Multi-Material Experts |

Paper/Plastic Hybrids, Laminated Structures |

Combined Printing Techniques |

7,500 units |

5-6 weeks |

Material Selection and Customization Solutions

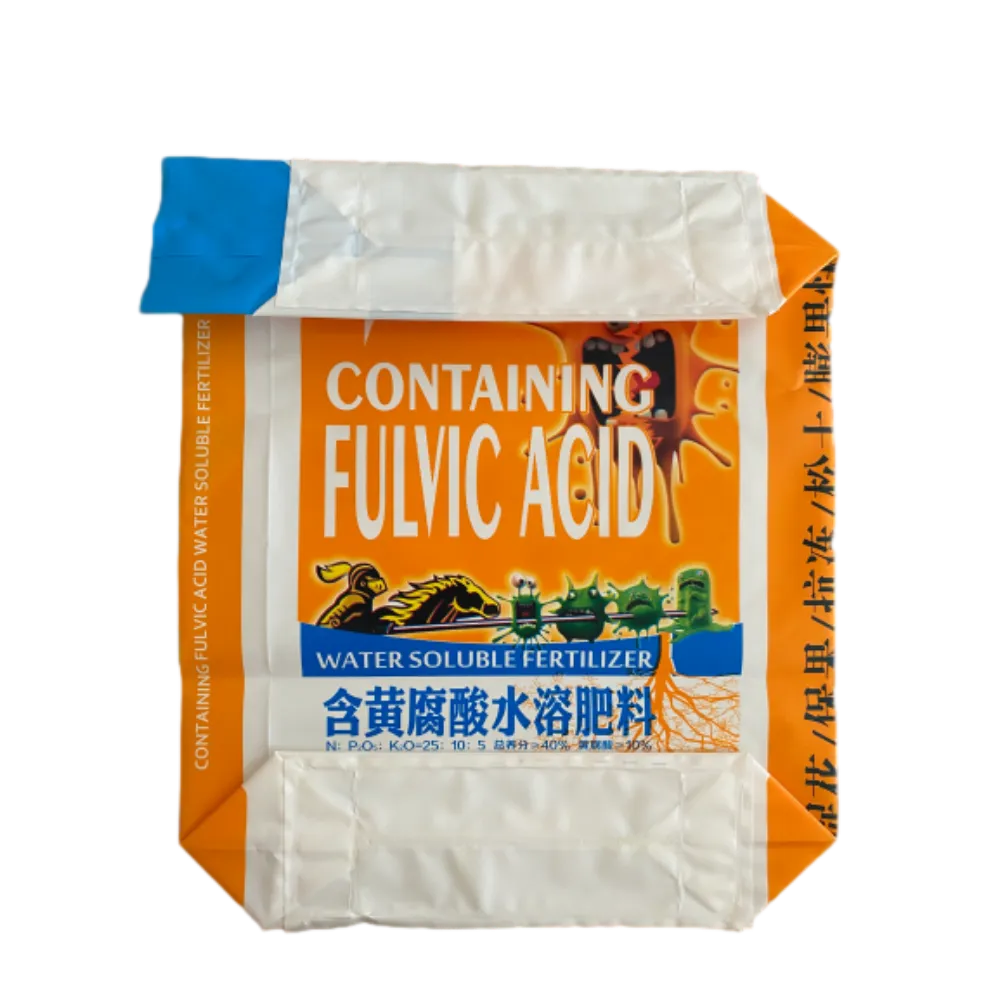

Material selection criteria extend beyond aesthetics to functional requirements and sustainability metrics. Applications require distinct material properties:

- Retail Boutiques: Cotton handle paper bags with reinforced bases supporting 15kg capacity

- Food Services: Multi-layer barriers preventing grease penetration while retaining recyclability

- E-commerce: Water-resistant mailers with puncture resistance exceeding ASTM D5278

Finishing options substantially impact brand perception. Case studies demonstrate custom handles increasing brand recall by 73%. Embossed logos elevate luxury positioning, while textured surfaces encourage product engagement. Production partners provide material samples testing packaging performance under temperature variations, humidity exposure, compression forces, and transportation simulations.

Demonstrated Applications Across Industries

Strategic packaging partnerships deliver tangible business outcomes. Luxury apparel brands leverage custom tissue paper inserts alongside surface-treated shopping bags, resulting in 32% higher social media sharing. Food industry leaders utilize resealable poly bags with custom barriers extending product freshness by 12 days. Several representative implementations:

- Global cosmetics brand increased accessory sales by 29% following packaging redesign with integrated display features

- Organic food supplier reduced damage claims by 41% after implementing custom tear-resistant pouches

- E-commerce electronics company eliminated secondary packaging using custom printed anti-static poly bags

- Specialty coffee roaster enhanced premium positioning through textured kraft bags with aroma-seal valves

Key Considerations When Selecting Packaging Manufacturers

Evaluating packaging production partners requires comprehensive assessment beyond cost. Multiple criteria determine successful partnerships:

- Compliance Capabilities: Certification scope including ISO 9001, ISO 14001, BRCGS packaging standards

- Geographical Footprint: Regional manufacturing hubs optimizing transportation emissions

- Material Traceability: Supply chain transparency meeting disclosure requirements

- Responsive Systems: Real-time order tracking and dynamic scheduling capabilities

Progressive manufacturers maintain relationships with multiple paper mills ensuring supply chain continuity. Technical support teams analyze client's distribution challenges before recommending solutions. Facilities producing under FDA food contact standards demonstrate superior contamination control protocols. Site visits often reveal operational excellence through five-S implementation and continuous improvement programs.

(custom paper bag manufacturers)

FAQS on custom paper bag manufacturers

Q: What customization options do custom paper bag manufacturers offer?

A: Custom paper bag manufacturers provide options like size variations, handle types (twisted, flat, or ribbon), and printing techniques (embossing, foil stamping, or digital printing) to match branding needs.

Q: Can custom plastic bag manufacturers use eco-friendly materials?

A: Yes, many custom plastic bag manufacturers offer biodegradable, recycled, or compostable materials, including options like rPET or plant-based plastics for sustainability-focused clients.

Q: What is the minimum order quantity (MOQ) for custom poly bag manufacturers?

A: MOQs vary but typically range from 5,000 to 10,000 units for custom poly bag manufacturers, depending on complexity, material, and printing requirements.

Q: How long does production take with custom paper bag manufacturers?

A: Production timelines average 2-4 weeks for custom paper bags, including design approval and printing, with expedited options available for urgent orders.

Q: Do custom plastic bag manufacturers handle full design services?

A: Many offer end-to-end services, including graphic design, prototyping, and print-ready file checks, ensuring compliance with technical specifications for plastic bags.