Heat seal aluminum foil bags have emerged as a staple in the packaging industry, driven by the increasing demand for superior storage solutions across various sectors such as food, pharmaceuticals, and electronics. These bags provide an unparalleled barrier against external elements, which is vital in preserving the integrity and quality of products.

With years of experience in the packaging realm, I can affirm the paramount importance of using high-quality materials for product preservation. Aluminum foil bags excel in their ability to resist moisture, oxygen, ultraviolet rays, and contaminants, making them an ideal choice for maintaining the freshness and efficacy of sensitive products. This expert insight underscores why many industries rely on these bags for their packaging needs.

The heat sealing process, which securely bonds the edges of the aluminum foil bag, ensures that contents remain protected from environmental influences. This technique involves using heat and pressure to melt adhesive layers on the bag’s edges, forming a tight seal. The reliability of this method is one reason why manufacturers trust these bags for storing perishable items and pharmaceuticals that require a controlled environment.

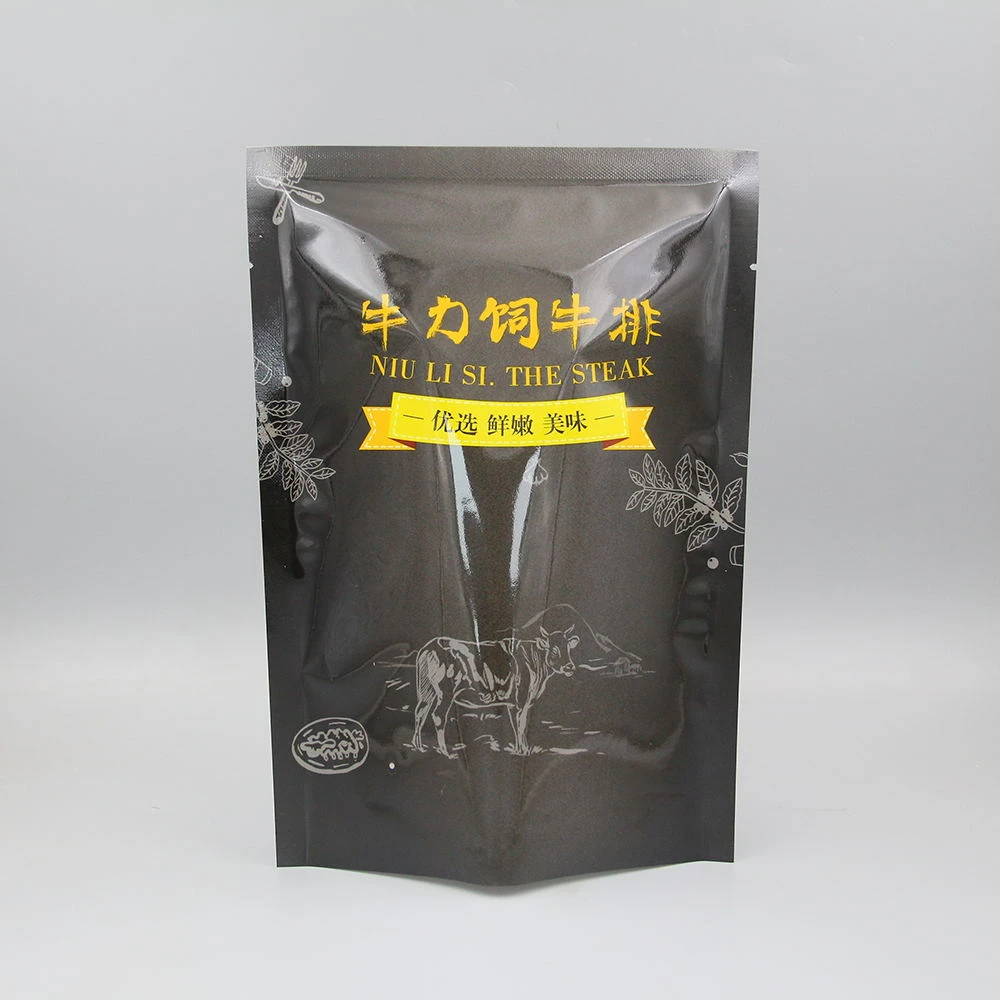

Beyond their robust protective qualities, heat seal aluminum foil bags offer versatility in design. Available in various sizes and shapes, they can cater to specific product requirements. Customization options, such as vacuum sealing, resealable zippers, and easy-open features, enhance their usability and consumer appeal. These variations not only cater to practical needs but also support branding efforts, making products stand out on retail shelves.

From a professional standpoint, the production and utilization of heat seal aluminum foil bags must adhere to industry standards and regulatory guidelines. For instance, in the food industry, these bags should meet the Food and Drug Administration (FDA) requirements for food contact materials, ensuring they do not compromise the safety or taste of food products. This compliance assures consumers of the trustworthiness and safety of the packaging.

heat seal aluminum foil bag

Observations from real-world applications paint a compelling picture of the efficiency of these bags. In the electronics sector, where static electricity can damage circuit boards, aluminum foil bags help dissipate static, safeguarding sensitive electronic components during shipment. This authoritative evidence demonstrates their critical role in protecting high-value, precision-engineered products.

Consumer feedback consistently highlights the benefits of using heat seal aluminum foil bags. Users often commend their durability, ease of use, and effectiveness in extending shelf life. Such testimonials enhance the credibility of these packaging solutions, further solidifying their position as a trusted choice in the market.

Furthermore, the sustainability aspect of these bags cannot be overlooked. Although primarily composed of aluminum, advancements in recycling technologies have made it feasible to reclaim and repurpose aluminum, contributing to resource conservation and environmental protection. Companies dedicated to sustainable practices appreciate this feature, aligning their packaging solutions with broader environmental goals.

In summary, the adoption of heat seal aluminum foil bags is a testament to their superior protective qualities, design flexibility, compliance with regulatory standards, and sustainability. Industries that prioritize product integrity and environmental responsibility find them indispensable. As more businesses and consumers acknowledge their value, these bags are poised to remain a pillar in the packaging industry, trusted for their reliability and performance.