Packing aluminium foil has evolved beyond its traditional uses, now playing a pivotal role in modern packaging solutions. Aluminium foil's flexibility, heat resistance, and impermeability make it unrivaled in preserving food products while maintaining freshness. The versatility of this material extends to a wide spectrum of applications, underscoring its essential contribution to various industries.

Among the primary advantages of packing aluminium foil is its unparalleled barrier protection. This attribute is indispensable for preserving perishable goods, extending their shelf life by shielding them from light, oxygen, moisture, and contaminants. This quality ensures that food products remain safe and unspoiled while retaining their original taste and nutritional value. Consequently, it becomes a preferred material in the food and beverage industry, catering to the stringent standards of packaging requirements.

Equally significant is its ability to withstand extreme temperatures, showcasing aluminium foil's competence in both high-heat and freezing conditions. This adaptability assures that products packaged in foil can endure temperature fluctuations without compromising their integrity or quality. As a result, packed goods are safeguarded from the rigors of transportation and storage in diverse environments, further emphasizing its reliability.

Economic efficiency is another critical consideration when manufacturing packaging materials. Aluminium foil offers an optimal balance between cost-effectiveness and durability. Though lightweight, it provides robust protection, reducing overall packaging material volume and weight. This aspect is instrumental in reducing shipping costs and minimizing environmental impact, aligning with eco-conscious practices increasingly adopted by industries worldwide.

From the perspective of a packaging expert,

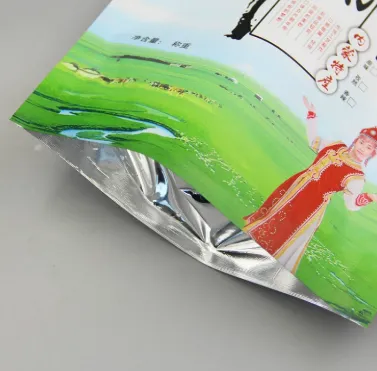

the versatility of aluminium foil is noteworthy. Its adaptability is proven in various formats, including laminate pouches, lids, blister packs, and trays, catering to different product specifications. This adaptability is instrumental for industries requiring custom packaging solutions that meet specific dimensions and functional requirements.

packing aluminium foil

An important consideration for businesses is the credibility of the packaging materials used. In this regard, aluminium foil shines due to its recyclable nature. With growing global awareness and regulatory pressures for sustainable packaging, the recyclability of aluminium foil addresses both ecological concerns and customer expectations for environmentally friendly practices. This makes it a sound choice for brand image enhancement, establishing trust and loyalty among eco-conscious consumers.

Moreover, the advances in technology have bolstered the applicability of packing aluminium foil. Coatings and laminates have been developed to further enhance its functionality. These enhancements can offer additional criteria like heat sealability and improved printability, making it a more attractive option for brands seeking aesthetically pleasing yet functional packaging. By providing an appealing presentation, aluminium foil helps increase consumer interest and purchase intent, further solidifying its importance in product marketing strategies.

Incorporating real-world applications, major food manufacturers have adopted aluminium foil due to its effective safeguarding properties. Companies that prioritize food safety and quality assurance appreciate the foil's role in ensuring compliance with health regulations. This commitment to quality and safety builds authoritativeness and trustworthiness among suppliers and consumers alike, further driving its extensive application across the food processing sector.

Navigating the complexities of packaging requirements, industries lean on aluminium foil for its proven reliability. Trust in its performance underpins its selection amidst a crowded market of alternatives. Companies that require high standards for packaging leverage the authoritative research and data supporting aluminium foil's efficacy across various environments and usage scenarios.

In conclusion, the role of packing aluminium foil in modern packaging extends well beyond traditional uses. Its extensive benefits—including protective barrier properties, temperature resilience, cost-effectiveness, and sustainability—establish it as a material that not only meets but exceeds the needs of contemporary manufacturing and distribution solutions. As it continues to innovate, aluminium foil proves itself indispensable, reflecting an unmatched commitment to quality, reliability, and environmental stewardship. Businesses leveraging this material not only align with best practices in packaging technology but also reinforce their market position with a sustainable, dependable choice that supports both consumer satisfaction and environmental responsibility.