Packing polythene, commonly referred to as polyethylene packaging, plays an indispensable role in the logistics and packaging industries due to its versatility, durability, and cost-effectiveness. Businesses worldwide rely on polyethylene for packaging due to its myriad benefits, which range from enhancing product longevity to optimizing transportation. Here, we delve into the intricacies of packing polythene, shedding light on its applications and why it remains a critical component of modern commerce.

One of the primary advantages of packing polythene is its strength-to-weight ratio. Polythene is remarkably lightweight yet incredibly resilient, making it an ideal choice for packaging goods without adding unnecessary weight. This characteristic is particularly beneficial for e-commerce businesses that depend on minimizing shipping costs while safeguarding products during transit. The intrinsic resilience of polythene ensures that products are protected from abrasions, moisture, and contaminants, thereby maintaining the integrity of the contents.

In terms of expertise,

it is essential to understand the different types of polyethylene used in packaging. Low-density polyethylene (LDPE) is commonly utilized for its flexibility and clarity, making it a popular choice for products that require visibility. Conversely, high-density polyethylene (HDPE) is chosen for its robustness, often used for products requiring enhanced protection. Selecting the right type of polyethylene is crucial for balancing product visibility with protection, thereby ensuring product appeal and safety.

Establishing authoritativeness in the realm of polyethylene packaging also involves staying abreast of technological advancements and innovations. Recent developments in biodegradable and recyclable polyethylene options address growing environmental concerns. These innovations cater to an eco-conscious market, allowing companies to maintain their commitment to sustainability while capitalizing on the durability of traditional polyethylene. Packaging solutions like polythene bags with d2w technology, which facilitates biodegradability, are gaining traction and providing businesses with viable eco-friendly alternatives.

packing polythene

Trustworthiness in polyethylene packaging is demonstrated through adherence to industry standards and certifications. Ensuring that packaging complies with regulations such as the ASTM D6400 or EN 13432 for compostability can enhance consumer trust and provide businesses with a competitive edge. Rigorous testing and quality control processes are imperative, as they guarantee that polyethylene products meet safety and environmental standards, further strengthening brand credibility.

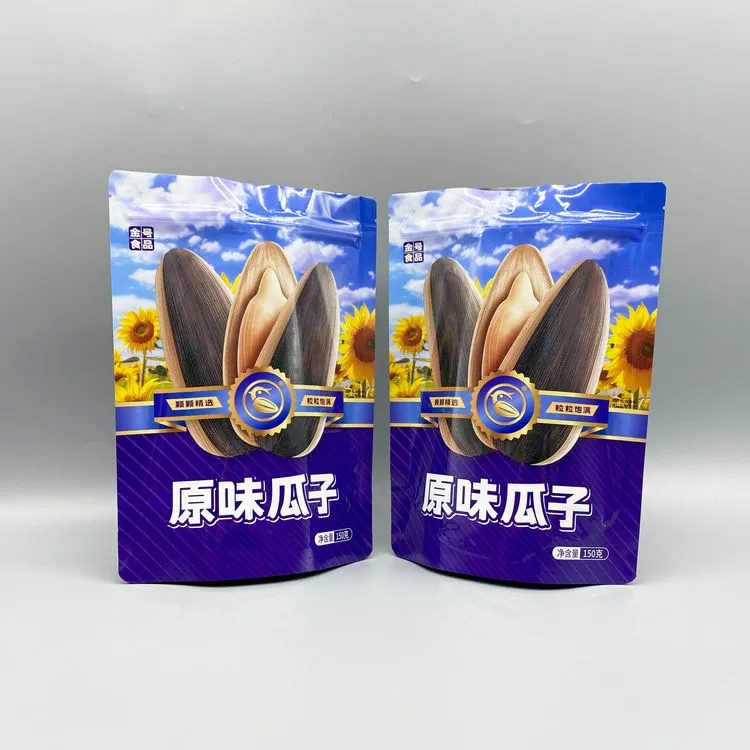

From a practical standpoint, the customizable nature of polyethylene packaging offers significant advantages for businesses aiming to create a distinct brand identity. Polyethylene materials can be tailored in terms of thickness, color, and printability, allowing for bespoke packaging solutions that resonate with target audiences. Branding opportunities through printed logos and personalized designs not only enhance visual appeal but also foster brand recognition and loyalty among consumers.

In the context of consumer experience, businesses must recognize the importance of user-friendly packaging. Easy-to-open designs and resealable options enhance the end-user experience, making polyethylene packaging a preferred choice for both businesses and consumers. The convenience of resealable polyethylene bags, for instance, ensures product freshness and reduces wastage, which is particularly important in the food industry.

To conclude, packing polythene is a cornerstone of modern packaging solutions, offering a balance of durability, flexibility, and sustainability. Its widespread adoption across various industries is a testament to its effectiveness in meeting the demands of contemporary commerce. By leveraging the strength of polyethylene and embracing sustainable innovations, businesses can enhance their logistical operations while bolstering brand reputation. As the packaging industry continues to evolve, polyethylene remains a vital material, underscored by its ability to adapt to changing market trends and consumer expectations.