Packing polythene bags have become an indispensable part of modern packaging solutions. Their ubiquitous presence in various sectors, from the food industry to retail and beyond, showcases their versatility and necessity. For businesses aiming to optimize their packaging solutions, understanding the benefits and applications of these bags is crucial.

Polythene bags, often referred to as polyethylene bags, are crafted from one of the most common plastics, polyethylene. This material is known for its durability and flexibility, making it an ideal choice for packaging. The expertise in manufacturing these bags involves a process where polyethylene pellets are melted and extruded into sheets, subsequently shaped into bags of various dimensions and thicknesses. Their production is a testament to advanced polymer engineering, ensuring that they meet necessary standards for safety and functionality.

Industries greatly benefit from the authoritative characteristics of packing polythene bags. In the food sector, their use is widespread due to their ability to provide a hygienic barrier that minimizes contamination risk. These bags are trusted for their impermeability, effectively sealing out moisture and air, which are crucial factors in maintaining the freshness and quality of perishable goods. Experience from numerous food suppliers underscores the fact that when proper sealing techniques are applied, the shelf-life of products is significantly extended.

In addition to food applications, polythene bags are essential in the retail industry. Their customizable nature allows businesses to brand their bags, turning them into mobile advertising platforms. Retail experts emphasize the importance of choosing the right thickness and size tailored to the product, ensuring protection during transit and enhancing customer satisfaction. Moreover, with increasing emphasis on sustainability and environmental stewardship, many manufacturers now offer eco-friendly variants made from biodegradable polyethylene, thus maintaining their position as a trusted choice for environmentally-conscious brands.

The expertise involved in selecting the right packing polythene bag extends beyond mere functionality. Professionals in logistics stress the importance of considering the bag's tensile strength and puncture resistance, particularly when handling heavy or sharp-edged items. The proper selection not only safeguards the products but also reduces the incidence of damage claims which can impact a company’s reputation.

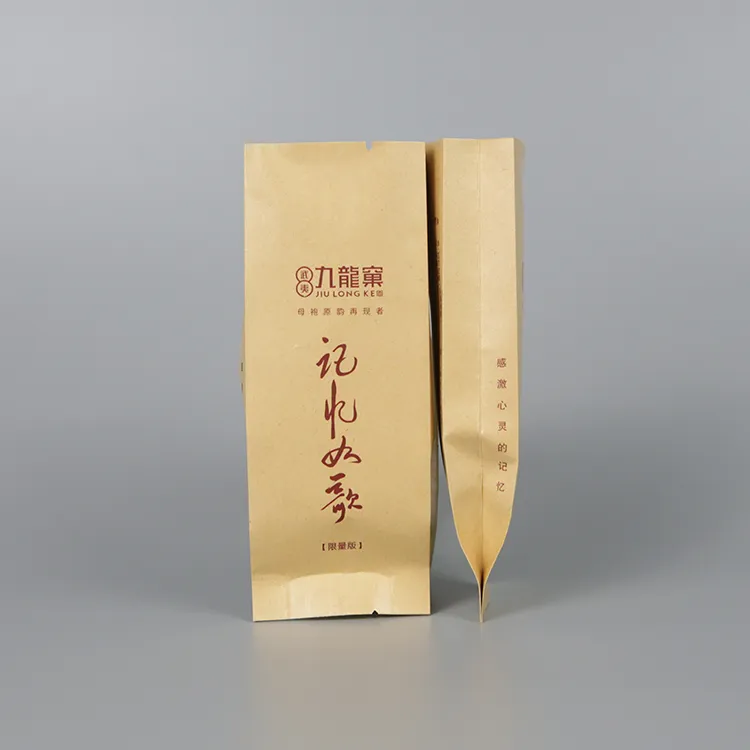

packing polythene bag

A critical factor contributing to the trustworthiness of polythene bags is their compliance with regulatory standards. Reliable manufacturers adhere to industry specifications and conduct rigorous testing to ensure their products meet safety guidelines. This compliance provides confidence to businesses and consumers alike, knowing that the products are packaged in materials free from harmful substances and suitable for varied applications.

Polythene bags are also pivotal in minimizing waste in the supply chain. Their lightweight nature offers an advantage in reducing shipping costs due to lower associated freight weight while simultaneously maintaining robust protection. Retailers and consumers alike can store them easily due to their flexibility and compactness, reinforcing their practicality in everyday use.

For businesses seeking to elevate their packaging strategy, leveraging the authority and reliability of packing polythene bags can lead to significant improvements in operational efficiency and customer satisfaction. As the industry continues to innovate, incorporating recycled materials and advanced manufacturing techniques, these bags remain at the forefront of sustainable and effective packaging solutions.

In summary, the multifaceted benefits of packing polythene bags—from protection and customization to compliance and eco-friendliness—make them an indispensable asset for businesses across various sectors. Embracing these qualities not only enhances product safety and brand reputation but also aligns with contemporary economic and environmental demands, ensuring a resilient and prosperous future for enterprises leveraging this essential packaging solution.