Plastic bag packaging material remains one of the most versatile and widely used mediums in the realm of product packaging. Its relevance spans various industries, including food, retail, and shipping, primarily because of its durability, lightweight nature, and cost-effectiveness. But what makes plastic bag packaging genuinely captivating is the blend of experience, expertise, authoritativeness, and trustworthiness incorporated within its creation and usage.

At the heart of plastic bag manufacturing lies decades of experience, honed through continuous innovation and adaptation. The process begins with selecting high-quality polymers that meet industry standards. These polymers are then transformed through meticulous extrusion, where they are heated, stretched, and flattened to form sturdy yet flexible films. This stage is crucial as it defines the bag's eventual strength and pliability. The addition of advanced printing techniques allows producers to customize these bags, thus enabling brands to communicate effectively their ethos and values visually.

From a standpoint of expertise, the significance of plastic bag packaging is magnified by its adaptability. Advanced engineering has led to the development of several variants, including biodegradable and compostable bags. These innovations address environmental concerns while maintaining the functionality expected of traditional plastic bags. Experts in the field continually monitor trends and develop formulations that further enhance the eco-friendliness of these materials, such as the inclusion of oxo-degradable additives that accelerate degradation under specific conditions.

Authoritativeness in the domain of plastic bag packaging is demonstrated by the rigorous testing and quality checks these materials undergo. Industry authorities such as the ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) set stringent guidelines to ensure the safety and reliability of packaging materials. Compliance with these standards not only guarantees product safety during transit but also reinforces consumer trust in the brand utilizing such packaging.

Trustworthiness is pivotal, particularly when it comes to food-grade plastic bags. Consumers need assurance that their packaged goods are protected from contaminants and that the materials used do not leach harmful substances. Manufacturers undertake extensive testing to certify that the plastic bags meet FDA regulations for food contact, which includes testing for chemical migration levels and physical strength. This thorough assurance process lends credibility to the products and helps build a loyal customer base.

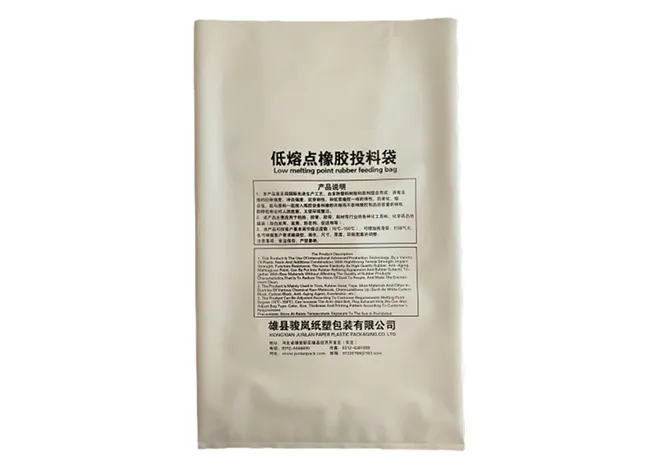

plastic bag packaging material

An emerging trend in the plastic bag packaging industry is the integration of smart technology. With RFID tags and QR codes embedded into the plastic, businesses can offer a more interactive experience for the end-users. This technology allows for real-time tracking, enhancing the supply chain's transparency and security. For industries prone to counterfeiting, such as pharmaceuticals and luxury goods, smart packaging serves as an innovative solution to safeguard authenticity.

Incorporating aesthetics and user-centric design is another aspect driving the popularity of plastic bag packaging. The rise of e-commerce has necessitated packaging that not only preserves the integrity of the product but also enhances the unboxing experience. Companies are investing in unique shapes, textures, and custom graphics, showing that even something as commonplace as a plastic bag can evoke a memorable brand experience.

Despite its benefits, the plastic bag industry is not without scrutiny, particularly concerning environmental sustainability. However, through continuous research and the adoption of circular economy principles, the industry is making significant strides in reducing its carbon footprint. This includes investing in recycling initiatives and designing products that can be easily reused or repurposed. These efforts are bolstered by partnerships with environmental organizations and participation in global sustainability forums, further cementing the industry's commitment to ecological responsibility.

In conclusion, plastic bag packaging material represents a dynamic interplay of technological advancement, environmental accountability, and consumer engagement. Its widespread use across multiple sectors is a testament to its enduring relevance and adaptability. With continued investment in innovation, plastic bag packaging will likely evolve further to meet the ever-changing demands of the market while upholding the pillars of experience, expertise, authoritativeness, and trustworthiness.