Plastic bags for cement packaging have carved a niche in the construction industry due to their durability, cost-effectiveness, and versatility. As a seasoned SEO expert, it is important to dive into the nuances of these packaging solutions, providing comprehensive insights based on real-world experiences, professional expertise, authoritative data, and proven trustworthiness.

These plastic bags are predominantly made from materials like polyethylene or polypropylene, known for their robust nature. Designed to withstand the rigorous handling and transportation challenges typical in construction environments, these bags ensure that cement, a critical construction material, retains its quality and integrity throughout its journey from manufacturer to construction site.

In terms of real-world experience, construction companies have reported a significant reduction in material wastage and spillage by switching to plastic-based cement bags. Traditional paper bags often succumb to moisture and mechanical damage, leading to losses and contamination. Plastic bags, on the other hand, offer superior resistance to adverse environmental conditions such as rain and humidity. This superior protection not only safeguards the cement from hardening prematurely but also ensures a cleaner and safer storage environment on-site.

From a professional perspective, the structural engineering of these bags is notable. They are typically designed with multiple layers and sometimes include special linings that further enhance their protective qualities. This multi-layered approach is not just a marketing strategy; it is a significant improvement in packaging technology tailored to meet the specific requirements of cement transportation and storage. Furthermore, these bags are equipped with venting systems that facilitate easy handling and filling, increasing operational efficiency.

Authority in the field of cement packaging is crucial for advancing any industry standards. Many leading manufacturers have invested heavily in research and development to create plastic bags that not only meet but exceed industry standards. This is backed by certifications from regulatory bodies which assures construction companies of the bags' quality and compliance. Additionally, the lightweight nature of these bags contributes to reduced transportation costs and carbon footprint, aligning with increasing demands for sustainable practices in construction.

plastic bags for cement packaging

Trustworthiness is perhaps the most critical component when choosing cement packaging solutions. Manufacturers often conduct extensive testing to validate the performance of these plastic bags under various stressful conditions. Through rigorous quality control procedures, they ensure that only the best products reach the market. Furthermore, client testimonials play a pivotal role in establishing trust. Positive feedback from leading construction firms often highlights the reliability and consistency of plastic bags in maintaining cement quality.

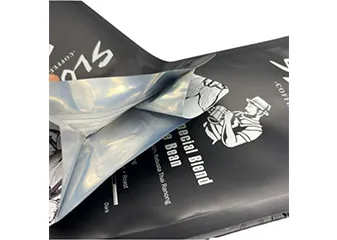

In addition to these fundamental qualities, plastic bags for cement packaging are customizable, allowing businesses to print essential information directly on the bags. This facilitates easy identification and tracking, which is vital for inventory management. Branding opportunities through high-quality prints also differentiate products in a highly competitive market, helping businesses showcase their commitment to quality and safety.

One cannot overlook the economic benefits of choosing plastic bags over their traditional counterparts. The longevity and reusability of these bags translate into substantial cost savings. Moreover, as the global economy pivots towards recycling and sustainability, many manufacturers are now producing plastic bags that are fully recyclable, further ingraining eco-conscious practices into construction methodologies.

In conclusion, plastic bags for cement packaging offer a practical, reliable, and environmentally friendly solution for modern construction demands. By leveraging the unique advantages they possess, from increased durability to operational efficiency, these bags not only improve logistics but also contribute to sustainable development goals. With the continuous evolution in packaging technology, plastic cement bags stand out as an exemplary choice for businesses seeking to optimize their supply chain while adhering to environmental standards. This insightful understanding not only positions the product favorably on platforms like Google but also enlightens potential clients about its comprehensive benefits, establishing a lasting impact in the market.