Plastic vacuum packing has transformed from a niche application into a cornerstone of modern packaging solutions. Its versatility and efficiency make it a popular choice for various industries, from food preservation to electronics. The process involves removing air from a package before sealing it, which offers numerous benefits including extended shelf life, reduced storage space, and enhanced product protection.

In the food industry, plastic vacuum packing has revolutionized storage techniques. It significantly extends the shelf life of perishable items by minimizing oxidation and inhibiting the growth of aerobic bacteria and fungi. This method not only maintains the freshness of food but also locks in flavors and nutrients, ensuring that consumers enjoy a product that tastes as good as the day it was packed. For restaurants and home cooks alike, vacuum packing is a practical solution to reduce food waste and optimize storage.

Beyond food preservation, plastic vacuum packing plays a crucial role in safeguarding sensitive electronic components. Moisture and air can lead to corrosion and other damaging effects on delicate electronic parts. By vacuum packing these items, manufacturers can ensure that products remain in pristine condition until they reach the end-user. This is particularly important in industries where reliability and precision are paramount, such as aerospace and medical device manufacturing.

The expertise required to execute effective plastic vacuum packing involves understanding materials and techniques. Not all plastics are created equal; choosing the right type of plastic film is vital for ensuring a strong seal and proper protection. Additionally,

different products may require specific vacuum environments or pre-packaging preparations. Professionals in this field must stay informed about the latest advancements in packing machinery and materials to offer the most efficient solutions.

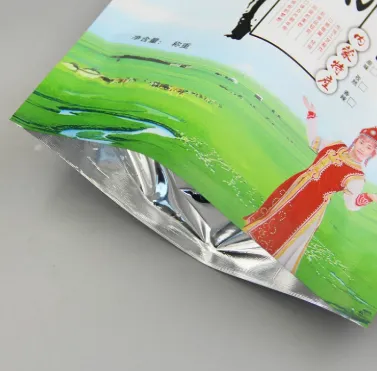

plastic vacuum packing

Authoritativeness in the field of vacuum packing is demonstrated by adherence to industry standards and regulations. These guidelines ensure that both the packaging materials and processes meet stringent safety and quality criteria. For food packaging, for example, compliance with food safety standards is non-negotiable. Companies that prioritize certification from recognized bodies further bolster their reputation as credible and reliable suppliers.

Trustworthiness in vacuum packing solutions is built on consistent results and customer satisfaction. Established companies in this domain offer not only high-quality packaging but also engage in sustainable practices. The environmental impact of plastic is a global concern, and leaders in vacuum packing are innovating with biodegradable or recyclable materials to address ecological issues. This commitment to sustainability without compromising performance reassures customers and builds long-term trust.

In conclusion, plastic vacuum packing represents a harmonious blend of science, innovation, and practicality. It caters to the diverse needs of various industries by providing superior preservation, protection, and space efficiency. Those looking to leverage this solution should seek partners with proven expertise and a commitment to sustainable practices. As technology and materials continue to advance, the capabilities and applications of vacuum packing are poised for exponential growth, promising even more sophisticated and eco-friendly solutions for the future.