- Introduction to HDPE Bags and Their Industrial Relevance

- Technical Advantages of PP and HDPE Bags

- Market Comparison: Leading HDPE Bag Manufacturers

- Customization Solutions for Woven and White HDPE Bags

- Application Case Studies Across Industries

- Sustainability and Recycling Metrics

- Choosing the Right HDPE Bags Manufacturer

(pp hdpe bags)

Understanding PP HDPE Bags and Industrial Demand

High-Density Polyethylene (HDPE) and Polypropylene (PP) bags are critical in industries requiring durable, moisture-resistant packaging. The global HDPE packaging market is projected to grow at a 5.8% CAGR from 2023 to 2030, driven by demand in agriculture, construction, and chemicals. White HDPE bags dominate the food sector due to UV resistance, while woven HDPE bags are preferred for heavy-duty applications like construction materials.

Technical Superiority in Material Performance

HDPE bags outperform alternatives like LDPE or PVC in tensile strength (20-25 MPa) and chemical resistance. Key benefits include:

- Reusability: Up to 5-year lifespan under standard conditions.

- Temperature tolerance: -50°C to 120°C without deformation.

- Printability: High-resolution graphics on white HDPE surfaces.

Manufacturer Comparison: Key Metrics

| Manufacturer |

MOQ |

Price Range (per 1k units) |

Production Capacity |

Certifications |

| Supplier A |

10,000 |

$180-$240 |

5M/month |

ISO 9001, FDA |

| Supplier B |

5,000 |

$210-$260 |

3.2M/month |

ISO 14001, BRC |

Tailored Solutions for Specific Needs

Customization options for woven HDPE bags include:

- Size variations: 10g to 50kg capacity

- Additives: Anti-static, flame-retardant, or biodegradable coatings

- Closure systems: Ziplock, heat-seal, or gusseted designs

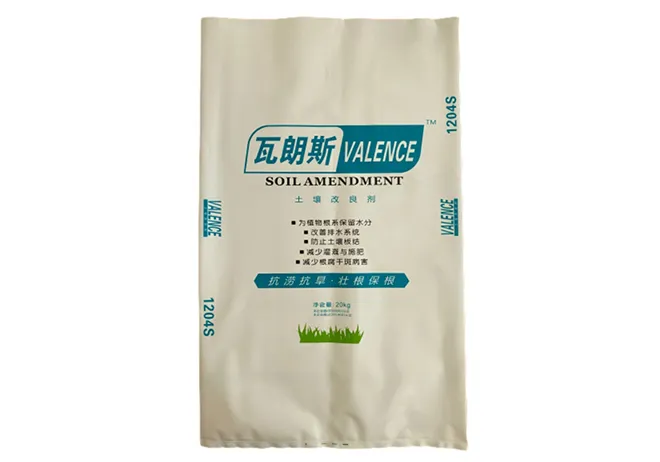

Real-World Application Success Stories

A fertilizer company reduced packaging waste by 37% after switching to UV-stabilized white HDPE bags with 6-color printing. In construction, a woven HDPE bulk bag solution decreased product loss during transportation by 52% for a cement manufacturer.

Environmental Impact and Circular Economy

Modern HDPE bags achieve 92-95% recyclability rates. Advanced manufacturers now integrate 30-40% post-consumer recycled content without compromising strength, aligning with EU Circular Economy Package targets.

Partnering with Expert HDPE Bags Manufacturers

Select manufacturers based on technical capabilities (e.g., multi-layer extrusion technology) and compliance history. Leading producers now offer digital twin simulations to preview bag performance before mass production, reducing development time by 65%.

(pp hdpe bags)

FAQS on pp hdpe bags

Q: What is the difference between PP and HDPE bags?

A: PP (Polypropylene) bags are lightweight and flexible, while HDPE (High-Density Polyethylene) bags offer higher tensile strength and durability. HDPE bags are better suited for heavy-duty packaging, whereas PP is ideal for lightweight applications. Both materials are recyclable and widely used in packaging.

Q: Why choose white HDPE bags for packaging?

A: White HDPE bags provide a clean, professional appearance and are often used for food-grade or medical packaging due to their non-toxic properties. The color white also allows for easy printing of logos or labels. They retain the durability and moisture resistance of standard HDPE bags.

Q: How to identify a reliable HDPE bags manufacturer?

A: Look for manufacturers with certifications like ISO standards, proven industry experience, and positive customer reviews. Reliable HDPE bags manufacturers often offer customization options and provide material quality test reports. Transparency in pricing and production timelines is also key.

Q: Are woven HDPE bags reusable and eco-friendly?

A: Yes, woven HDPE bags are reusable, tear-resistant, and designed for multiple uses. They are eco-friendly as HDPE is 100% recyclable, reducing environmental impact. These bags are ideal for agricultural, industrial, and bulk storage applications.

Q: Can HDPE bags be customized for specific industries?

A: Absolutely. HDPE bags manufacturers offer customization in size, thickness, printing, and UV stabilization. Industries like agriculture, construction, and chemicals often request reinforced handles or laminated layers for specialized needs. Custom colors, including white HDPE bags, are also available.