PVC packing sheets, renowned for their versatility and durability, have become a staple in the packaging industry. With an ever-increasing demand across various sectors, understanding the practical applications and benefits of these sheets can elevate the effectiveness of your packaging solutions.

PVC, or Polyvinyl Chloride, is a synthetic plastic polymer that has gained popularity due to its exceptional properties. These sheets stand out because of their durability, resistance to moisture, and adaptability. Their structure allows them to withstand harsh environmental conditions, ensuring the protection of the contents they encase. This feature is particularly beneficial for industries dealing with fragile or moisture-sensitive products, ensuring they reach the end consumer in pristine condition.

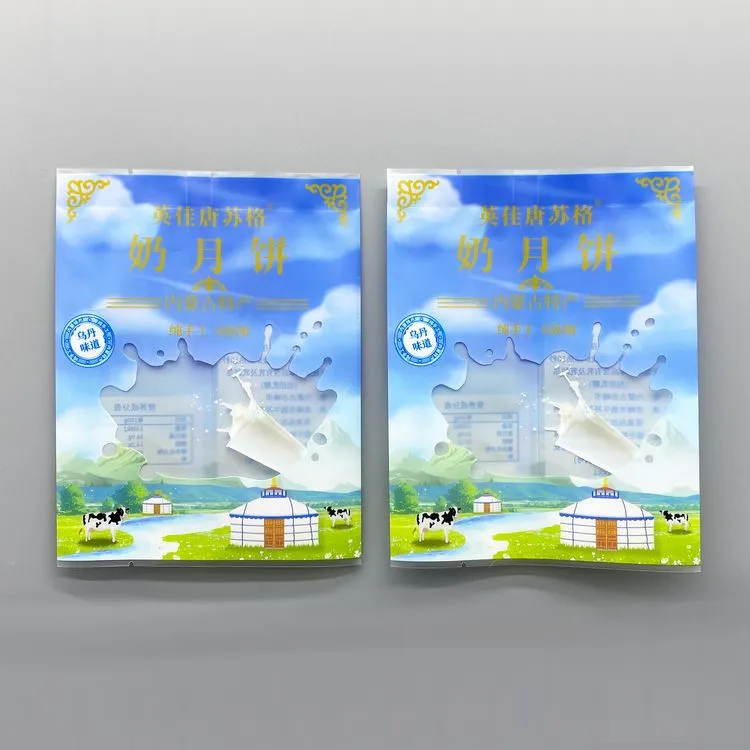

The flexibility of PVC sheets is another advantageous attribute. Available in various thicknesses and sizes, they can be customized to suit specific packaging needs. Whether it's for wrapping large industrial components or delicate consumer electronics, PVC sheets can be adjusted to provide optimal protection and presentation. This flexibility also extends to their printing options. Businesses can enhance their branding by opting for PVC sheets that accommodate vibrant and clear print designs without compromising the material’s integrity.

From an expertise perspective, selecting the right PVC packing sheet involves understanding its chemical and mechanical properties. These sheets are lauded for their low permeability to gases and water vapor, a feature that enhances their protective capabilities. Additionally, they boast impressive tensile strength and resilience, ensuring longevity and repeated use without wear and tear. For industries focusing on sustainability, it's noteworthy that while PVC is a plastic, advancements in recycling technologies have increased the feasibility of reusing these sheets, reducing environmental impact.

pvc packing sheet

PVC packing sheets are predominantly used in food packaging, electronics, pharmaceuticals, and construction. In the food industry, the non-toxic nature of PVC when treated appropriately makes it suitable for wrapping food items, ensuring freshness and preventing contamination. Electronics benefit from the antistatic variety of PVC sheets, which protect sensitive components from electrostatic discharge. In pharmaceuticals, these sheets provide a barrier against moisture and contaminants, crucial for maintaining the efficacy of medicinal products. Meanwhile, in construction, PVC sheets serve as moisture barriers, protecting building materials from environmental damage.

As an authoritative voice in the packaging sector, PVC packing sheets offer companies an opportunity to achieve cost-effective and reliable packaging solutions. Their production is streamlined, and the availability of these sheets worldwide ensures that companies can maintain consistency in their packaging processes. Trusted manufacturers offer certifications guaranteeing that their PVC sheets meet international safety and quality standards, further assuring businesses and consumers of their reliability.

Trustworthiness in PVC packing sheets is also derived from their longstanding use and the continuing innovation in their production. The legal framework surrounding their production and use is stringent, ensuring that manufacturers adhere to environmental and safety regulations. Businesses opting for PVC sheets can benefit from an assurance of quality supported by decades of research and innovation.

In conclusion,

PVC packing sheets provide a comprehensive solution for diverse packaging challenges. Their adaptability, strength, and protective qualities, combined with the ability to support detailed branding efforts, make them a valuable resource for businesses. Furthermore, the ongoing commitment to improving their sustainability profile ensures that PVC sheets will remain a relevant and reliable choice for packaging needs in the future. Whether for protecting, displaying, or transporting products, PVC packing sheets stand as a testament to innovation in material science, offering efficiency and reliability to a myriad of industries worldwide.