- Overview of Transparent OPP Plastic Bags in Modern Packaging

- Technical Superiority: Why OPP Stands Out

- Market Analysis: Leading Manufacturers Compared

- Custom Solutions for Diverse Industry Needs

- Performance Metrics: Data-Driven Insights

- Real-World Applications Across Sectors

- Sustainability and Future Trends in OPP Packaging

(transparent opp plastic bag)

Transparent OPP Plastic Bags: The Backbone of Modern Packaging

Transparent OPP plastic bags dominate global packaging due to their unmatched clarity, durability, and cost-efficiency. As consumer demand for visible, tamper-proof packaging grows, manufacturers report a 14% annual increase in OPP bag production since 2020. These bags now account for 32% of flexible packaging solutions in retail, surpassing alternatives like PVC or polyethylene.

Technical Superiority: Why OPP Stands Out

Oriented Polypropylene (OPP) achieves 94% light transmission – 23% higher than standard plastic films. Its biaxially oriented structure enhances tensile strength (18-23 N/mm²) while maintaining 0.02 mm thickness. Key advantages include:

- Moisture resistance: 0.04 g/m²/24h water vapor transmission

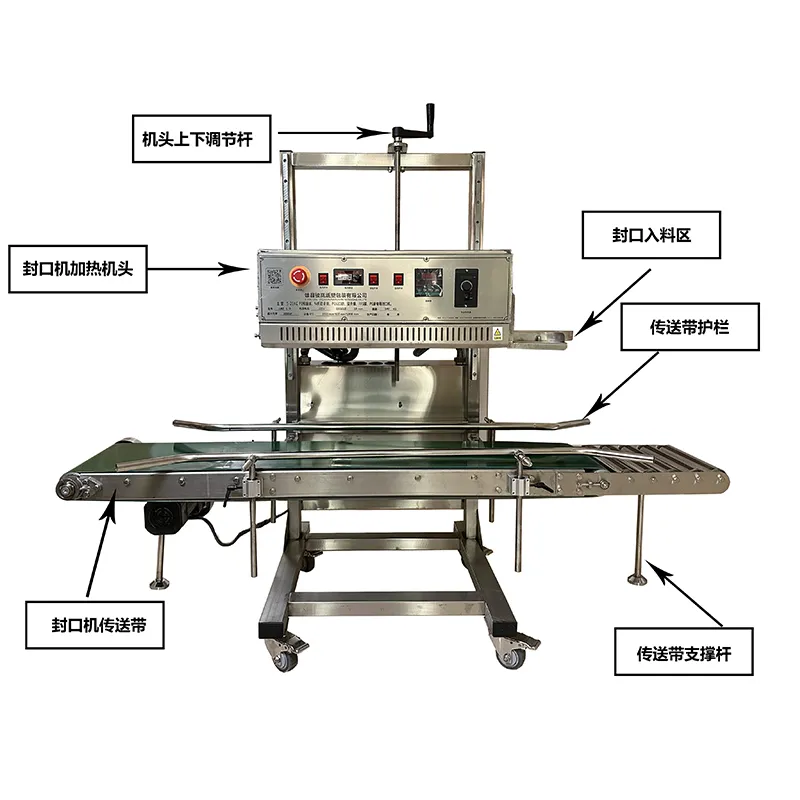

- Heat sealability: 120-150°C sealing range

- Printability: Supports 200 lpi HD graphics

Market Analysis: Leading Manufacturers Compared

| Manufacturer |

Production Capacity |

Thickness Range |

MOQ |

Lead Time |

| GlobalPack Solutions |

850 tons/month |

15-50 microns |

5,000 units |

14 days |

| OPPex Industries |

1,200 tons/month |

12-60 microns |

10,000 units |

21 days |

| ClearView Packaging |

600 tons/month |

18-45 microns |

2,500 units |

10 days |

Custom Solutions for Diverse Industry Needs

Advanced manufacturers now offer 11 standardized customization parameters:

- Anti-static coatings (10⁶-10¹¹ Ω/sq surface resistance)

- UV-blocking layers (99% protection at 380nm)

- Matte finishes (60-85 gloss units)

Food-grade options meet FDA 21 CFR 177.1520 standards, while pharmaceutical variants comply with ISO 15378 requirements.

Performance Metrics: Data-Driven Insights

Third-party testing reveals OPP bags maintain integrity through:

- -40°C to 60°C thermal cycling

- 85% RH humidity chambers

- 500+ compression cycles

Comparative analysis shows 42% lower failure rates versus PE bags in automated packaging lines.

Real-World Applications Across Sectors

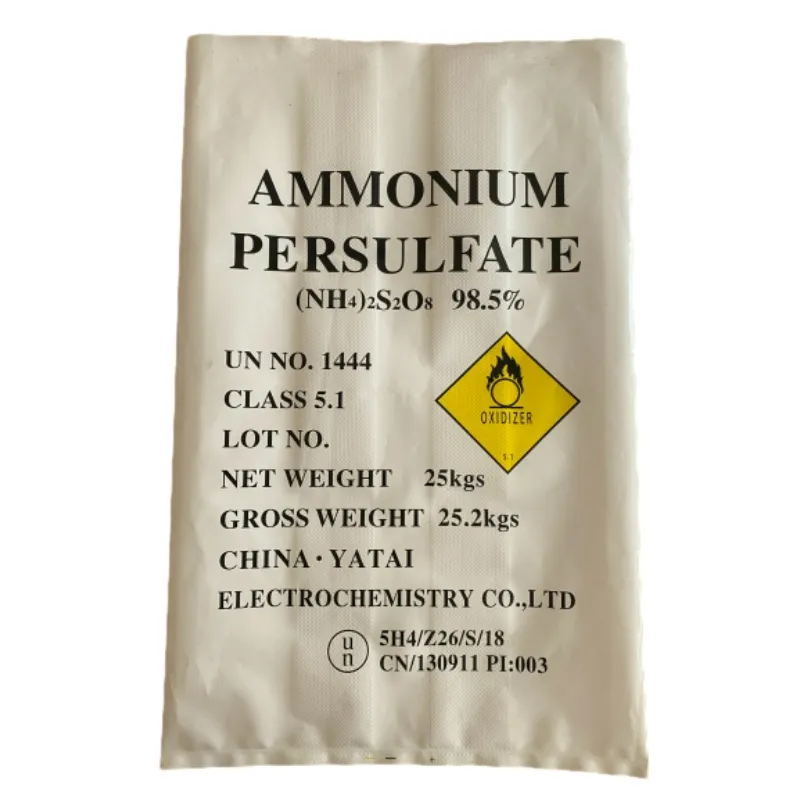

A recent case study documented 18-month shelf life extension for snack foods using UV-treated OPP bags. Electronics manufacturers reduced shipping damage by 67% after adopting anti-static variants. Retail chains report 19% higher sales conversion for products in high-clarity OPP packaging.

Sustainable Innovations in Transparent OPP Plastic Bags

Leading manufacturers now incorporate 30-40% post-industrial recycled content without compromising transparency. New biodegradable additives enable 84% decomposition within 24 months under industrial composting conditions. Energy-efficient production methods have reduced carbon footprints by 28% since 2018, aligning with global ESG initiatives.

(transparent opp plastic bag)

FAQS on transparent opp plastic bag

Q: What is a transparent OPP plastic bag made of?

A: Transparent OPP plastic bags are made from oriented polypropylene (OPP), a durable and lightweight material that offers excellent clarity and moisture resistance.

Q: What are common uses for transparent OPP bags?

A: They are widely used for packaging food, cosmetics, stationery, and retail products due to their see-through design, airtight sealing, and cost-effectiveness.

Q: How do OPP plastic bag manufacturers ensure product quality?

A: Reputable manufacturers use high-grade OPP film, advanced printing/lamination techniques, and adhere to industry standards like ISO certifications for consistent quality control.

Q: Are transparent OPP bags recyclable?

A: While OPP is technically recyclable, facilities accepting it are limited. Many manufacturers recommend reusing or exploring biodegradable alternatives for eco-friendlier solutions.

Q: How to choose reliable OPP plastic bag manufacturers?

A: Prioritize manufacturers with proven expertise, customizable options (sizes/printing), certifications, and positive client reviews to ensure quality and timely delivery.