The Evolution of Flexible Packaging: A Deep Dive into automatic packaging film

In the rapidly evolving landscape of modern manufacturing and logistics, the efficiency and reliability of packaging solutions are paramount. The global demand for streamlined production lines and extended product shelf life has propelled automatic packaging film to the forefront of industrial innovation. This specialized material, often engineered from advanced polymer blends, is indispensable for high-speed, automated packaging systems across diverse sectors. It offers significant advantages over traditional manual methods, including superior consistency, reduced labor costs, and enhanced product protection. The market trend indicates a clear shift towards sustainable and high-barrier film solutions, driven by increasing consumer awareness regarding environmental impact and the need for greater food safety. For instance, the demand for sophisticated barrier properties in packaging films has seen a substantial surge in the food and pharmaceutical industries, necessitating innovations in co-extrusion and lamination technologies to preserve product integrity and extend freshness without compromising on operational efficiency. As industries strive for leaner operations and more robust supply chains, the strategic adoption of optimized packaging films becomes a critical competitive differentiator, directly influencing operational uptime and overall profitability.

Furthermore, the increasing complexity of supply chains, coupled with stringent regulatory requirements for product traceability and safety, underscores the critical role of high-performance packaging films. Industries such as food and beverage, pharmaceuticals, personal care, and industrial goods heavily rely on automated systems for consistent and secure packaging. The shift towards flexible packaging formats, including various types of automatic packaging film, offers benefits such as reduced material usage, lower transportation costs, and increased product visibility on retail shelves. Innovations in film technology now allow for features like easy-open seals, reclosable zippers, and anti-fog properties, catering to specific consumer demands and product attributes. The integration of smart packaging features, such as QR codes for supply chain tracking or temperature indicators, further enhances the value proposition of these films. This continuous evolution reflects a commitment to not only protect products but also to enhance the entire packaging ecosystem, providing tangible value from the manufacturing floor to the end-consumer experience, ultimately reducing waste and improving product longevity.

Manufacturing Process: Precision Engineering for Superior Performance

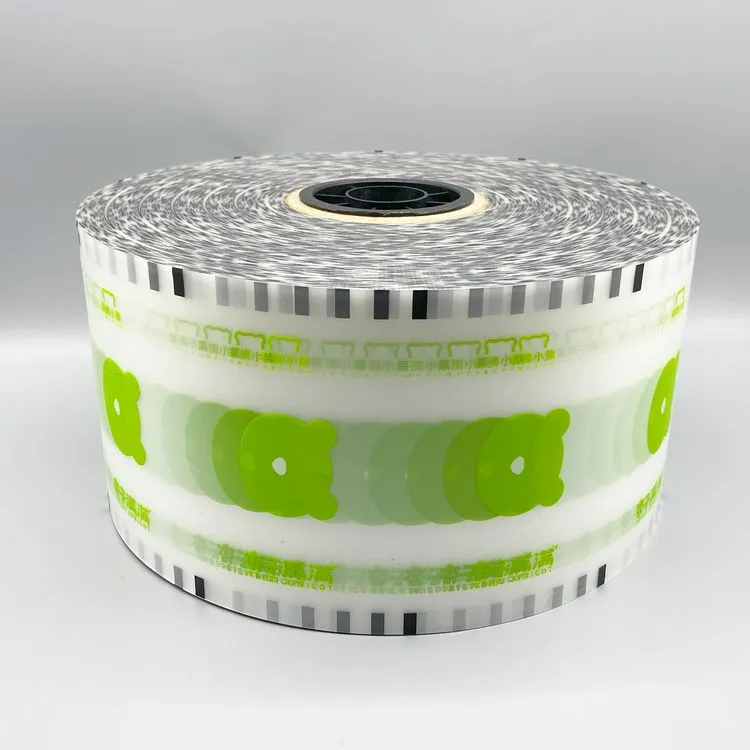

The production of Automatic Packaging Film Roll involves a meticulously controlled, multi-stage manufacturing process designed to achieve specific material properties essential for high-speed automated lines and diverse application requirements. This begins with the careful selection of virgin polymer resins, typically including polyethylene (PE), polypropylene (PP), PET, nylon, and EVOH, chosen for their distinct mechanical, barrier, and optical characteristics. The first key stage is extrusion, where these raw polymer pellets are melted and pushed through a die to form a continuous sheet. This can be done via blown film extrusion for superior strength and puncture resistance or cast film extrusion for excellent clarity and uniformity. Post-extrusion, many films undergo co-extrusion, where multiple layers of different polymers are simultaneously extruded and bonded together to create a composite film with enhanced barrier properties, such as resistance to oxygen, moisture, and aroma, critical for products like food packaging pouch.

Following extrusion, a critical phase is lamination, where different film layers, often including metallized films or aluminum foil, are combined using advanced adhesive systems to impart additional barrier protection, structural integrity, and aesthetic appeal. This multi-layer construction is paramount for achieving the extended shelf life and protective qualities demanded by sensitive products. For example, a common structure for high-barrier automatic packaging film might involve a printable outer layer, a robust core layer for strength, and an inner sealant layer that ensures secure seals. Quality control is integrated throughout the entire process, adhering to stringent international standards such as ISO 9001 for quality management systems and potentially industry-specific certifications like FDA compliance for food packaging pouches. Regular testing includes tensile strength, puncture resistance, oxygen transmission rate (OTR), water vapor transmission rate (WVTR), and seal integrity tests to guarantee consistent performance. The final stages involve slitting the wide film rolls into precise widths and lengths required by clients' packaging machines, followed by meticulous winding onto cores, ensuring tension consistency and roll quality. This comprehensive process ensures each Automatic Packaging Film Roll delivers optimal performance, minimizing downtime in high-speed operations and maximizing product protection across diverse applications.

Technical Parameters and Specifications of Automatic Packaging Film

Understanding the precise technical parameters of automatic packaging film is crucial for selecting the optimal material for specific applications, directly impacting machine efficiency, product preservation, and overall packaging costs. These parameters define the film's suitability for various product types, packaging machinery, and environmental conditions. Key specifications include film thickness, typically measured in microns (µm), which affects yield, barrier properties, and material cost. Material composition, detailing the types and proportions of polymers (e.g., PE, PP, PET, Nylon, EVOH) and any additives, determines the film's mechanical strength, heat sealability, and barrier performance against gases and moisture. For example, a higher EVOH content generally indicates superior oxygen barrier capabilities, vital for oxygen-sensitive foods.

Other critical metrics include tensile strength, elongation at break, and puncture resistance, which are indicative of the film's durability and ability to withstand the rigors of automated packaging lines and transportation. The coefficient of friction (COF) is vital for smooth operation on machinery, ensuring the film feeds consistently without snagging or slipping. Optical properties like clarity, haze, and gloss contribute to product visibility and shelf appeal. Furthermore, specific barrier properties, such as Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR), measured in cm³/(m²·24h) and g/(m²·24h) respectively, quantify the film's effectiveness in protecting contents from atmospheric degradation. Heat seal strength and temperature range are also paramount for creating secure, reliable seals on high-speed equipment. Below is a comprehensive table outlining typical specifications for various types of automatic packaging film rolls, providing a benchmark for performance evaluation and material selection.

| Parameter |

Standard (Range) |

Typical Application Relevance |

| Film Thickness |

15 µm - 200 µm |

Impacts yield, barrier, and mechanical strength; optimized for specific product weight and protection level. |

| Tensile Strength (MD/TD) |

40 - 150 MPa |

Film's resistance to breaking under tension, crucial for machine runnability and package integrity. |

| Elongation at Break (MD/TD) |

200% - 700% |

Flexibility and ability to stretch before breaking, important for irregular product shapes. |

| Puncture Resistance |

10 - 50 N (ASTM D3763) |

Protection against sharp edges or impacts during transit and handling, critical for bulky or sharp products. |

| Oxygen Transmission Rate (OTR) |

0.1 - 100 cm³/(m²·24h·atm) @ 23°C, 0% RH (ASTM D3985) |

Determines shelf life for oxygen-sensitive products (e.g., snacks, fresh meat). Lower is better. |

| Water Vapor Transmission Rate (WVTR) |

0.5 - 50 g/(m²·24h) @ 38°C, 90% RH (ASTM F1249) |

Crucial for moisture-sensitive products (e.g., dried foods, pharmaceuticals). Lower is better. |

| Coefficient of Friction (COF) |

0.2 - 0.5 (Kinetic) |

Ensures smooth feeding and sealing on high-speed packaging machinery, preventing jams. |

| Heat Seal Temperature Range |

120°C - 180°C |

Indicates the optimal temperature window for consistent and strong seals on packaging equipment. |

Application Scenarios and Strategic Advantages

The versatility of automatic packaging film allows for its extensive application across a broad spectrum of industries, providing tailored solutions that meet unique challenges. In the food sector, where product freshness and safety are paramount, these films are extensively used for packaging snacks, frozen foods, fresh produce, dairy products, and ready-to-eat meals. Their superior barrier properties, including oxygen and moisture resistance, are critical for extending shelf life, preventing spoilage, and maintaining sensory qualities. For instance, modified atmosphere packaging (MAP) often utilizes specific film compositions to create an optimal environment inside the food packaging pouch, significantly delaying spoilage and retaining product appeal. Beyond food, the pharmaceutical industry relies on films with stringent barrier properties to protect medicines from degradation due to light, moisture, and oxygen, ensuring drug efficacy and patient safety.

In the personal care and cosmetics industry, these films offer aesthetic appeal alongside robust protection for items like wipes, lotions, and soaps, with custom printing capabilities enhancing brand visibility. Industrial applications range from packaging automotive parts to building materials, where films provide crucial protection against dust, moisture, and physical damage during storage and transit. A primary advantage is the significant energy saving achieved through reduced material usage compared to rigid packaging, leading to lower transportation costs and a smaller carbon footprint. The inherent flexibility and adaptability of these films also allow for diverse packaging formats, from stand-up pouches to flow-wraps, catering to varied market needs and consumer preferences. Furthermore, advancements in film technology contribute to enhanced corrosion resistance for metal components and improved hygiene in sectors like medical device packaging, underscoring their critical role in ensuring product integrity and operational efficiency across a global supply chain. This comprehensive utility demonstrates how modern films contribute to sustainability initiatives and optimized logistical pathways.

Technical Advantages and Customization Solutions

The technical prowess of contemporary automatic packaging film lies in its ability to deliver multifaceted benefits that optimize both product protection and operational efficiency. One significant advantage is superior machinability, ensuring seamless compatibility with high-speed automated packaging machinery. This minimizes downtime, reduces material waste, and maximizes throughput, directly contributing to a lower total cost of ownership for packaging operations. The precision engineering allows for consistent film unwinding, accurate sealing at specified temperatures, and reliable cutting, all critical for maintaining continuous production cycles. Furthermore, these films are designed for excellent printability, supporting high-resolution graphics and vibrant colors, which are essential for brand messaging and shelf appeal, especially for competitive markets such as food packaging pouches.

Beyond standard offerings, customization is a core strength, allowing manufacturers to tailor film properties to precise client specifications. This includes adjusting film thickness for optimal barrier-to-cost ratios, incorporating specialized additives for UV protection, anti-fog properties, or enhanced slip for easier handling. Specific barrier layers can be engineered to combat oxygen, moisture, light, or aroma permeation, depending on the product's sensitivity and desired shelf life. For instance, packaging for sensitive electronics might require anti-static properties, while certain food products may demand a specific OTR to maintain freshness. Our commitment to ISO 9001 quality management ensures that every customized solution adheres to the highest standards of production and performance. Our extensive service tenure in the industry, coupled with numerous successful partnerships with leading brands globally, stands as a testament to our authoritative position and proven capability in delivering reliable, high-performance packaging solutions that meet the evolving demands of modern industry.

Manufacturer Comparison and Application Case Studies

When evaluating suppliers for automatic packaging film, potential partners must consider several critical factors beyond mere cost. A reputable manufacturer distinguishes itself through adherence to international quality standards such as ISO and FDA compliance, demonstrating a commitment to safety and consistency. Our company's long-standing service history and robust portfolio of collaborations with multinational corporations underscore our authoritative position and extensive experience in the flexible packaging industry. We prioritize transparent data-driven performance metrics, providing comprehensive testing reports and certifications for our film products, which include details on OTR, WVTR, tensile strength, and seal integrity, offering a clear benchmark for quality and reliability. In contrast, some lesser-known manufacturers may offer lower prices but often compromise on material quality, consistency, and technical support, leading to potential production bottlenecks, increased waste, and compromised product integrity in the long run.

Consider a real-world application case: a leading snack food producer faced challenges with their existing packaging film, experiencing high rates of package breakage during transit and a limited shelf life for their delicate potato chips. After consulting with our technical team, we engineered a custom co-extruded automatic packaging film with enhanced puncture resistance and an optimized oxygen barrier. The new film not only significantly reduced breakage rates by 30% but also extended the product's shelf life by an additional two weeks, directly impacting market reach and reducing food waste. This success story illustrates our capability to provide tailored solutions that address specific client pain points, leveraging our expertise and advanced manufacturing processes. Our rigorous internal testing protocols, combined with third-party validation, provide the quantitative evidence necessary for B2B decision-makers to trust our products and services, ensuring peace of mind and operational excellence. This commitment to proven performance differentiates us in a competitive market, solidifying our role as a trusted partner for critical packaging needs.

Trust and Support: Our Commitment to Clients

At the core of our operations is a steadfast commitment to building and maintaining client trust through unwavering transparency, robust support, and clear guarantees. We understand that investing in automatic packaging film is a critical decision impacting production lines and brand reputation. Our trustworthiness is reinforced by our comprehensive quality assurance protocols, which involve stringent in-house testing and third-party certifications to validate film performance against industry standards. We provide detailed certificates of analysis (COA) with every batch, ensuring complete traceability and adherence to specified technical parameters. This commitment to empirical data offers our partners the confidence that our products will consistently perform as expected under real-world industrial conditions. Our long-standing relationships with global partners and a high rate of repeat business serve as empirical evidence of our reliability and dedication to client satisfaction, fostering long-term collaborative success.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom order of Automatic Packaging Film Roll?

A: Standard lead times for custom orders range from 4 to 6 weeks, depending on the complexity of the film structure and current production queue. Expedited options are available upon request and project evaluation.

- Q: What are your quality control standards?

A: We operate under ISO 9001 certified quality management systems. All films undergo rigorous testing for thickness uniformity, tensile strength, seal integrity, OTR, and WVTR to ensure compliance with specifications and international standards like FDA for food packaging pouches.

- Q: Do you offer technical support for machine compatibility?

A: Yes, our technical support team provides comprehensive guidance on film selection, machine setup, and troubleshooting to ensure seamless integration and optimal performance on your specific packaging machinery.

- Q: What is your warranty policy for packaging film products?

A: We offer a standard warranty covering material defects and ensuring performance aligns with agreed-upon specifications for a defined period from the date of delivery. Detailed warranty terms are provided with each quotation.

Our streamlined delivery process, optimized for efficiency, ensures that orders reach our clients on schedule, minimizing any potential disruptions to their production timelines. We leverage a robust logistics network, capable of handling both domestic and international shipments with meticulous care and transparency. Furthermore, our dedicated customer support team is available to address any inquiries, provide technical assistance, and facilitate a smooth ordering and delivery experience. From initial consultation and custom film design to after-sales support and technical troubleshooting, our commitment extends across the entire client journey, reinforcing our reputation as a trusted and reliable partner in the flexible packaging industry.

References

- Smith, J. (2022). "Advancements in Flexible Packaging Materials for Food Applications." Journal of Packaging Technology.

- Zhang, L. (2021). "The Role of Barrier Films in Extending Shelf Life of Perishable Goods: A Comprehensive Review." International Journal of Food Science and Technology.

- European Plastics Converters (EuPC). (2023). "Sustainable Packaging Solutions: Trends and Innovations in Polymer Films." EuPC Annual Report.

- Global Packaging Institute. (2024). "Market Analysis: Growth Drivers and Challenges in Automatic Packaging Film Segment." GPI Industry Outlook.

- International Standards Organization (ISO). (2023). "ISO 9001:2015 Quality management systems - Requirements."