Understanding PE Packaging Bags in Industrial Applications

Polyethylene (PE) packaging solutions are fundamental across a vast spectrum of B2B sectors, offering unparalleled versatility and performance for various industrial and commercial needs. The demand for reliable, durable, and cost-effective packaging drives continuous innovation in this field. This comprehensive guide delves into the intricate world of പെ പാക്കേജിംഗ് ബാഗ്, examining its manufacturing processes, technical specifications, diverse applications, and critical advantages in the modern supply chain. From material science to end-user benefits, we aim to provide an authoritative resource for decision-makers and technical professionals seeking optimal packaging solutions.

Current Industry Trends and Market Dynamics for PE Bag Packaging

The global flexible packaging market, significantly influenced by പെ പാക്കേജിംഗ് ബാഗ്, is projected to reach approximately USD 350 billion by 2028, with a compound annual growth rate (CAGR) of around 4.5% from 2023. This growth is largely driven by increasing demand from food and beverage, pharmaceutical, and industrial sectors, alongside a growing emphasis on sustainable packaging. Key trends include:

- Sustainability Focus: Manufacturers are increasingly investing in recyclable and biodegradable PE formulations. The rise of mono-material PE structures facilitates easier recycling, addressing environmental concerns without compromising performance.

- Advanced Barrier Properties: Innovations in multi-layer co-extrusion technologies are enhancing barrier properties against moisture, oxygen, and UV light, crucial for extending product shelf life in various applications. The development of PA/PE plastic bags, for instance, offers superior puncture resistance and barrier performance.

- Lightweighting: Reducing material thickness while maintaining strength is a key objective, contributing to lower raw material consumption, reduced transportation costs, and a smaller carbon footprint.

- Smart Packaging: Integration of features like QR codes, NFC tags, and temperature indicators is emerging, providing enhanced traceability and consumer engagement, particularly relevant for high-value or sensitive goods.

- Customization and Digital Printing: The demand for bespoke pe pouches with high-quality graphics and variable data printing is on the rise, enabling brands to differentiate products and run targeted campaigns.

Manufacturing Process Flow of PE Packaging Bag

The production of high-quality PE packaging bags involves a precise and controlled multi-stage manufacturing process, ensuring consistent product integrity and performance. The primary material, Polyethylene, is selected for its excellent chemical resistance, flexibility, and heat-sealability. Depending on specific requirements, different grades of PE (LDPE, LLDPE, HDPE, MDPE) or co-extrusions with PA (Polyamide) are utilized for enhanced properties.

1. Material Selection and Preparation

- Resin Procurement: High-grade PE resins (e.g., Dow, ExxonMobil, LyondellBasell) are selected based on desired mechanical strength, clarity, barrier properties, and heat resistance. For high-performance applications, co-polymers like PA/PE plastic bags are chosen for their superior puncture and barrier characteristics.

- Additive Blending: Resins are often blended with various additives such as anti-block agents, slip agents, UV stabilizers, anti-static agents, and colorants to achieve specific performance attributes and aesthetic requirements.

2. Extrusion Process (Film Production)

- Blown Film Extrusion: This is the most common method. PE pellets are fed into an extruder, melted, and forced through a circular die to create a continuous tube of molten plastic. Air is then injected into the center of the tube, expanding it into a bubble (casting). The bubble is cooled, flattened by nip rollers, and wound into a roll of film. This process allows for precise control over film thickness and width, forming the basis for pe pouches.

- Cast Film Extrusion: For applications requiring higher clarity and gloss, molten PE is extruded through a flat die onto a chilled roller, rapidly cooling it into a film. This method is often used for multi-layer films, including PA/PE plastic bags.

Schematic Steps:

- Raw Material Feeding (PE Pellets + Additives)

- Melting & Homogenization in Extruder

- Die Forming (Circular for Blown, Flat for Cast)

- Bubble/Film Cooling

- Film Winding onto Rolls

3. Printing and Converting

- Printing: Flexographic or rotogravure printing techniques are used to apply graphics, branding, and product information onto the film. High-resolution printing ensures appealing aesthetics for pe bag packaging.

- Lamination (Optional): For multi-layer structures (e.g., PA/PE for enhanced barrier), films are laminated together using adhesives. This significantly boosts durability and barrier performance.

- Bag Forming: The printed and/or laminated film is fed into a bag-making machine. Here, precise cutting and heat-sealing operations form the desired bag style (e.g., flat pocket, stand-up pouch, gusseted bag). Advanced machines ensure consistent seal strength and dimensions for every പെ പാക്കേജിംഗ് ബാഗ്.

4. Quality Control & Testing

Stringent quality control measures are applied throughout the process to ensure compliance with international standards and client specifications. Key tests include:

- Material Properties: Melt Flow Index (MFI), Density, Tensile Strength (ASTM D882), Elongation, Puncture Resistance (ASTM D3763).

- Barrier Performance: Oxygen Transmission Rate (OTR - ASTM D3985) and Water Vapor Transmission Rate (WVTR - ASTM F1249).

- Seal Strength & Integrity: Heat seal strength (ASTM F88), Leak detection (bubble test, dye penetration).

- Visual Inspection: Clarity, color consistency, print registration, and absence of defects.

Manufacturers often adhere to standards like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). For food contact applications, compliance with FDA (e.g., 21 CFR 177.1520 for PE) and EU food safety regulations is mandatory. Typical service life for PE packaging ranges from 1-5 years, depending on storage conditions and environmental exposure.

Technical Specifications for PE Plastic Bags Supplier Offerings

A reputable പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ provides detailed technical specifications to ensure customers receive products precisely tailored to their application requirements. Below is a representative table for a standard Flat Pocket PE bag, reflecting common industry parameters.

Product Specification Table: Flat Pocket PE Bag

| Parameter |

Description |

Typical Range/Value |

Test Method/Standard |

| Material Type |

Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), High-Density Polyethylene (HDPE), or Co-ex (PA/PE) |

Varies by application |

ASTM D1505 (Density) |

| Film Thickness |

Gauging of the film for strength and flexibility |

30 to 200 microns (µm) / 1.2 to 8.0 mil |

ASTM D374 |

| Tensile Strength (MD/TD) |

Resistance to breaking under tension (Machine Direction / Transverse Direction) |

15-30 MPa (LDPE), 20-40 MPa (LLDPE), 25-50 MPa (HDPE) |

ASTM D882 |

| Elongation at Break (MD/TD) |

Ability to stretch before breaking |

300-700% (LDPE), 400-800% (LLDPE), 100-600% (HDPE) |

ASTM D882 |

| Puncture Resistance |

Resistance to penetration by sharp objects |

150-400 N (depending on thickness/material) |

ASTM D3763 |

| Seal Strength |

Force required to separate a heat seal |

Minimum 3.0 N/mm |

ASTM F88 |

| Clarity/Haze |

Optical property indicating transparency |

5-20% (LDPE),

| ASTM D1003 |

| Oxygen Transmission Rate (OTR) |

Rate at which oxygen permeates through the film (cc/m²/day) |

800-2000 (standard PE),

| ASTM D3985 |

| Water Vapor Transmission Rate (WVTR) |

Rate at which water vapor permeates through the film (g/m²/day) |

5-20 (standard PE),

| ASTM F1249 |

| Temperature Range |

Operational temperature range |

-40°C to +80°C |

Internal Testing |

Application Scenarios & Case Studies for PE Pouches

വൈവിധ്യം പെ പാക്കേജിംഗ് ബാഗ് makes it indispensable across diverse target industries. Its adaptability to various forms like pe pouches, flat bags, and barrier films addresses specific logistical and preservation challenges.

Typical Application Industries:

- Food & Beverage: Packaging for frozen foods, fresh produce, dry goods (grains, snacks), dairy products, and beverages. PE's non-toxic nature and excellent moisture barrier are crucial here.

- Pharmaceutical & Medical: Sterile packaging for medical devices, unit-dose packaging for drugs, and protective covers for equipment. High-purity PE and gamma-sterilizable films are common.

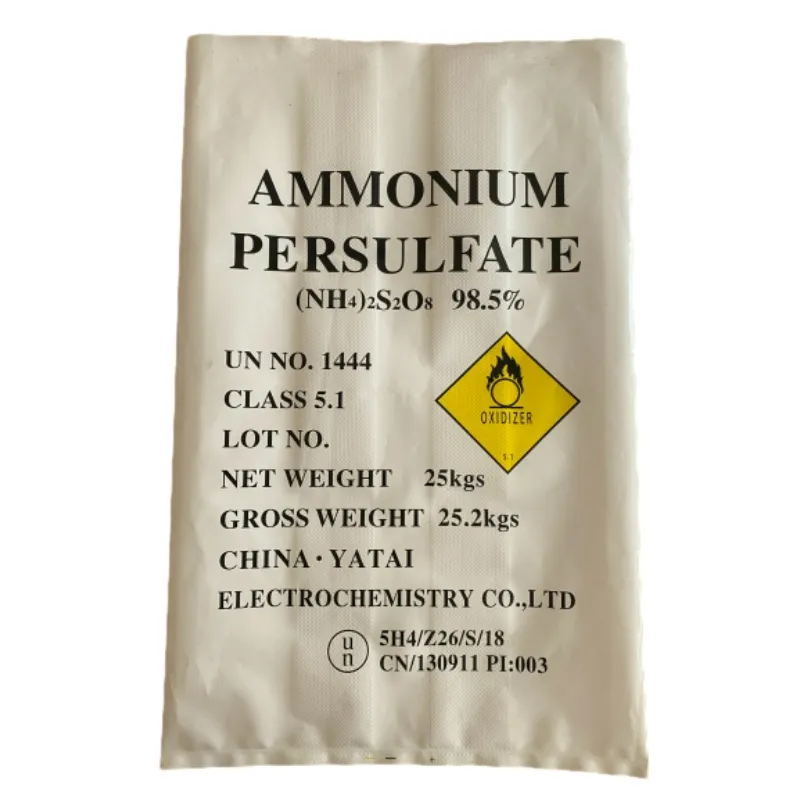

- Chemical & Petrochemical: Lining for drums and container111s, packaging for powders, granules, and corrosive liquids. The chemical inertness and robust film strength are key.

- Agriculture: Mulch films, greenhouse covers, silage bags, and packaging for seeds, fertilizers, and animal feed. UV stability and weather resistance are vital.

- Textile & Apparel: Garment bags, protective covers for linens, and packaging for raw textile materials.

- Logistics & E-commerce: Mailer bags, protective wraps, and pallet covers for secure transportation and storage.

Application Case Studies:

Case Study 1: Extended Shelf Life for Processed Meats

A leading food processor needed to extend the shelf life of their pre-sliced deli meats without using excessive preservatives. By switching to co-extruded PA/PE plastic bags, featuring high oxygen and moisture barrier properties, they achieved a 30% increase in product shelf life, reducing waste and expanding distribution capabilities. The robust puncture resistance also minimized in-transit damage, leading to significant cost savings in returns and re-shipments. Customer feedback highlighted improved freshness perception.

Case Study 2: Secure Packaging for Industrial Chemicals

A chemical manufacturer required secure and corrosion-resistant inner liners for bulk container111s of corrosive industrial salts. Standard PE films often showed stress cracking under specific chemical exposure. Collaborating with a specialized പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ, they implemented custom-formulated HDPE liners with enhanced chemical resistance and thicker gauges. This solution significantly reduced leakage incidents by 95% over a year, demonstrating superior corrosion resistance and ensuring worker safety and environmental compliance.

Technical Advantages of Advanced PE Packaging Solutions

Modern പെ പാക്കേജിംഗ് ബാഗ് solutions offer a multitude of technical advantages that directly translate into operational efficiencies and product protection for B2B clients:

- Superior Moisture Barrier: PE inherently provides an excellent barrier against water vapor, crucial for protecting hygroscopic products (e.g., powders, electronics) from moisture ingress, thus extending shelf life and preventing degradation.

- Chemical Resistance: PE exhibits high resistance to a wide range of acids, bases, and organic solvents, making it ideal for packaging chemicals, fertilizers, and other corrosive substances without material degradation or leaching. This ensures product integrity and safety.

- Exceptional Puncture and Tear Resistance: Especially with LLDPE or PA/PE co-extrusions, these bags offer robust mechanical strength, safeguarding contents during handling, transportation, and storage, particularly for heavy or irregularly shaped items.

- Heat Sealability: PE's low melting point and excellent heat-sealing properties allow for strong, consistent, and hermetic seals, ensuring product freshness and preventing contamination. This is vital for automated packaging lines.

- Cost-Effectiveness and Lightweighting: PE is one of the most economical polymers. Advances in film extrusion allow for thinner, yet stronger, films, reducing material usage, freight costs, and overall packaging expenditure. This contributes to energy saving throughout the supply chain.

- Recyclability: Monolayer PE films are widely recyclable, aligning with global sustainability initiatives and reducing environmental impact. Suppliers are increasingly focusing on circular economy principles for PE bag packaging.

- Flexibility and Adaptability: PE can be easily processed into various forms, including custom-sized bags, rolls, and pouches, with options for printing, lamination, and specialized features (e.g., zippers, spouts, vents).

- Food Contact Approved: Many grades of PE are approved by regulatory bodies like the FDA for direct food contact, ensuring product safety and compliance for food and beverage applications.

Vendor Comparison: Choosing the Right PE Plastic Bags Supplier

Selecting the optimal പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ is a critical strategic decision. It goes beyond mere price comparison and involves evaluating capabilities, quality, and support. Below is a framework for comparing potential vendors:

Vendor Comparison Criteria Table:

| Criteria |

High-Performing Supplier |

Average Supplier |

| Quality Certifications |

ISO 9001, ISO 14001, FDA/EU Food Contact, BRCGS Packaging. Robust internal QC. |

Basic ISO certification, limited or no food-specific approvals. |

| Product Customization |

Extensive capabilities: custom dimensions, gauges, material blends (e.g., PA/PE), printing, features (zippers, spouts, vents). |

Limited customization, standard sizes/materials, basic printing. |

| Technical Expertise & Support |

Dedicated technical sales, R&D support, material science knowledge, problem-solving. Proactive communication. |

Standard sales team, limited technical depth, reactive support. |

| Lead Times & Reliability |

Consistent on-time delivery, transparent scheduling, emergency order capabilities, robust supply chain. |

Variable lead times, occasional delays, less transparent. |

| Sustainability Initiatives |

Recyclable options, post-consumer recycled (PCR) content, energy-efficient production, waste reduction programs. |

Minimal or no specific sustainability efforts beyond basic recycling. |

| Pricing & Value |

Competitive pricing, strong ROI through product performance, long-term partnership focus. |

May offer lower initial price but potentially higher total cost of ownership due to quality or service issues. |

Customized Solutions for Optimal PE Bag Packaging

The "one-size-fits-all" approach rarely succeeds in industrial packaging. Specialized പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ offer extensive customization options to ensure the final product perfectly aligns with specific operational, branding, and protective requirements.

- Material Blends: Tailoring the PE resin blend (e.g., LLDPE for stretch, HDPE for rigidity, or co-extruded PA/PE plastic bags for high barrier) to achieve precise mechanical, thermal, and barrier properties. This includes food-grade and medical-grade options.

- Dimensions and Gauge: Exact bag width, length, and film thickness (gauge) configured to match product size, weight, and handling conditions, minimizing material waste and maximizing protection.

- Bag Styles: Beyond standard flat pockets, options include stand-up pouches (SUPs) with bottom gussets, side-gusseted bags, reclosable zipper bags, spouted pouches for liquids, and vacuum seal bags.

- Printing and Graphics: High-definition flexographic or rotogravure printing for vibrant branding, product information, QR codes, and regulatory labels. Matte or gloss finishes are available.

- Functional Features: Adding specific features like tear notches for easy opening, reclosable zippers, one-way degassing valves, hang holes, ergonomic handles, or anti-static properties for sensitive electronics.

- Barrier Enhancement: Integrating additional layers or coatings (e.g., EVOH, PVDC) into multi-layer films to boost oxygen, moisture, or aroma barrier properties for highly sensitive products.

- Anti-Corrosion and UV Protection: Incorporating Volatile Corrosion Inhibitors (VCI) into films for metal parts, or UV stabilizers for outdoor applications like agricultural films or products exposed to sunlight.

Ensuring Trustworthiness and Client Satisfaction

Building long-term B2B relationships relies heavily on trust, transparency, and reliable service. A leading പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ integrates these principles into every facet of their operation, from inquiry to after-sales support.

Frequently Asked Questions (FAQ):

Q1: What is the minimum order quantity (MOQ) for custom PE packaging bag?

A1: MOQs typically vary based on complexity, film thickness, and printing requirements. For custom printed designs, MOQs can start from 10,000 to 50,000 units. For plain bags, it might be lower, starting from 5,000 units. Please contact our sales team for precise figures based on your specifications.

Q2: Can your PE bags be recycled?

A2: Yes, our standard monolayer PE bags are 100% recyclable in regions with appropriate PE recycling infrastructure (e.g., #2 HDPE or #4 LDPE streams). We also offer options with post-consumer recycled (PCR) content and mono-material solutions to enhance recyclability.

Q3: How do I determine the correct film thickness for my product?

A3: Our technical team will consult with you to assess your product's weight, dimensions, fragility, handling requirements, and desired protection level. Factors like puncture resistance, tear strength, and barrier needs will guide the optimal film gauge recommendation.

Q4: Do you offer samples of your pe pouches?

A4: Yes, we provide generic samples of our existing products free of charge. For custom samples, a small fee might apply depending on the complexity, which is often credited against a confirmed order.

Q5: What are the lead times for custom orders?

A5: Lead times vary depending on the product complexity, order volume, and current production schedule. Typically, new custom orders require 4-6 weeks for production after artwork approval. Repeat orders can be fulfilled within 2-4 weeks.

Lead Time & Fulfillment Details:

We prioritize efficient order fulfillment. Our lead times for custom PE packaging bag typically range from 4 to 6 weeks for initial orders involving new tooling or complex printing. Repeat orders benefit from streamlined processes, reducing lead times to 2-4 weeks. We maintain robust inventory management and flexible production scheduling to meet urgent demands where possible. Clients receive transparent updates throughout the production and delivery cycle.

Warranty & After-Sales Support:

All our പെ ബാഗ് പാക്കേജിംഗ് solutions come with a comprehensive quality warranty, ensuring they meet the agreed-upon specifications and performance standards. In the unlikely event of a manufacturing defect, we commit to prompt investigation, replacement, or credit. Our dedicated after-sales support team is available to assist with any technical queries, application challenges, or feedback post-delivery, ensuring continuous operational excellence for our clients. We strive to build lasting partnerships based on trust and consistent performance.

Conclusion

The evolution of പെ പാക്കേജിംഗ് ബാഗ് reflects a dynamic industry driven by innovation, sustainability, and the critical need for reliable product protection. From advanced material science to intricate manufacturing processes, and through diverse application scenarios, PE packaging continues to be an indispensable component of global B2B supply chains. By partnering with a knowledgeable and technologically advanced പ്ലാസ്റ്റിക് ബാഗ് വിതരണക്കാരൻ, businesses can leverage customized solutions that not only safeguard their products but also enhance operational efficiency, reduce environmental impact, and build stronger brand presence. Investing in high-quality PE packaging is an investment in product integrity, logistical excellence, and long-term business success.

References

- Smith, J. (2022). "Polyethylene: Properties, Processing, and Applications." John Wiley & Sons.

- Market Research Future. (2023). "Flexible Packaging Market Research Report - Global Forecast till 2030." Retrieved from www.marketresearchfuture.com.

- ASTM International. (Various Standards). "Standards for Plastics and Packaging." Retrieved from www.astm.org.

- FDA. (2023). "21 CFR 177.1520 Olefin Polymers." Retrieved from www.accessdata.fda.gov.

- European Union. (Various Regulations). "Regulation on plastic materials and articles intended to come into contact with food." Retrieved from www.eur-lex.europa.eu.