Explore the latest in bulk stand up pouches, technical data, industry certifications, comparing top suppliers, and how to tailor the perfect stand up pouch at scale. Dive into manufacturing insights, parameter trend charts, and real-world application cases.

1. Industry Overview: Bulk Stand Up Pouches Market Trends 2024

The global bulk stand up pouches

market exceeded USD 5.1 billion in 2023 and is projected to grow at 7.2% CAGR (Source: MarketsandMarkets). Key drivers include the flourishing food & beverage, pet food, pharmaceuticals, and personal care sectors. Increasing demand for stand up pouch wholesale and customized stand up zip pouches wholesale

underlines the shift toward eco-friendly, high-barrier, visually appealing packaging.

Latest Market Facts (2023-2024):

- Asia-Pacific dominated the market (42% share), driven by China and India as major exporters.

- Food sector accounted for 61% of bulk stand up pouch application demand in 2023.

- Sustainability: Over 37% of orders now request recyclable or biodegradable laminated films.

- Value-Added Features in demand: zipper closures, spouts, UV-print, and transparent windows

2. Technical Parameter Table – Core Specs for Bulk Stand Up Pouches

Selection of bulk stand up pouches is based on thickness, barrier rating, closure style, laminates, and print capability. Below is an industry standard data set.

Bulk Stand Up Pouches - Technical Specifications (Standard Types)

| Type |

Material Structure |

Thickness (microns) |

Closure |

Barrier Property (OTR/WVTR) |

Size Range (mm) |

Surface Print |

Certifications |

| Standard Pouch |

BOPP/VMPET/PE or PET/PE |

80–120 |

Heat Seal |

≤40 / ≤9 |

90×140 to 350×530 |

8 colors rotogravure |

FDA, ISO 9001 |

| Stand Up Zip Pouches |

PET/AL/PE (Aluminum Barrier) |

100–160 |

Zip Lock |

≤2 / ≤0.6 |

100×150 to 300×450 |

Digital, UV |

FDA, SGS, BPA-free |

| Kraft Paper Pouch |

Kraft/BOPP/PE |

90–130 |

Zip Lock |

≤85 / ≤11 |

110×160 to 280×380 |

Flexo Ink |

ISO 22000, FSC |

| Spout Pouch |

PET/NY/PE |

110–170 |

Spout, Cap |

≤4 / ≤0.9 |

120×200 to 280×440 |

UV + Window |

FDA, BPA-free |

| Recyclable Pouch |

Mono PE/PO |

85–120 |

Zip/Seal |

≤60 / ≤8 |

100×170 to 300×420 |

Digital |

RecyClass, FDA |

3. Manufacturing Process – How Bulk Stand Up Pouches Are Made

Step 1: Substrate Preparation

Film rolls (BOPP, PET, AL, PE) are quality-checked for tensile strength and welded joints (in compliance with ISO 1184, ASTM D882).

Step 2: Laminating & Metallizing

Advanced solventless or dry-bond lamination: laminates BOPP/PET to VMPET or aluminum foil for enhanced oxygen/moisture barrier (see barrier data above). Metallizing provides 97–98% light barrier, per ANSI and FDA guidelines.

Step 3: Printing

Multi-web high-speed gravure (8–10 colors) or digital inkjet ensures vibrant branding. UV-cured surface increases chemical/solvent resistance (ref: ISO 2836 standards).

Step 4: Pouch Forming & Cutting

Pouch machines (e.g., Totani, Mespack) use rotary dies and CNC-plated knives to ensure ±0.2mm dimensional tolerance—even at 120cpm speed.

Step 5: Closure/Spout Application

Zipper tracks or spout fitments/valves are ultrasonically sealed for leakproof packaging (AQL 1.5, per ISO 2859-1).

Step 6: Quality Inspection & Compliance Testing

100% inspection for seal strength (ASTM F88), OTR/WVTR (MOCON), drop/vibration (ISTA), and hygiene audits (ISO 22000, FDA).

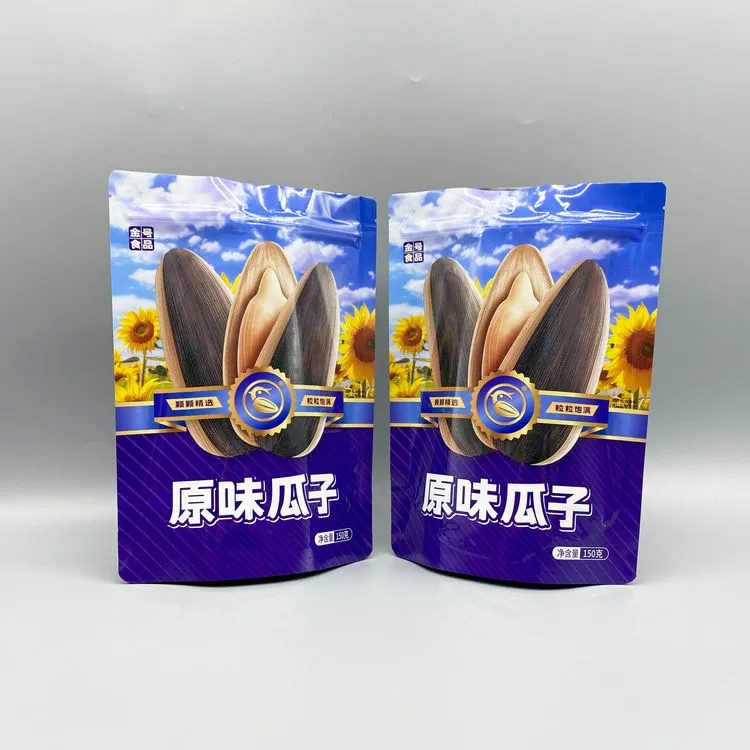

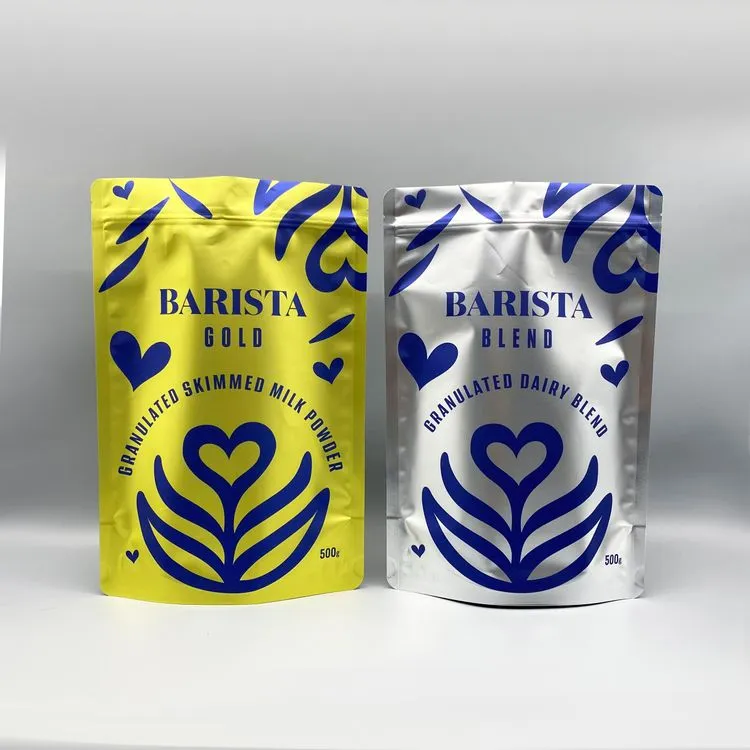

4. Product Focus: Standing Packaging Bag (by Junlanpack)

The Standing Packaging Bag is designed to outperform in multiple industries with its

multi-layer film structure and high-barrier performance. Its material engineering (PET/AL/PE or Kraft/PET/PE) ensures durability, print quality, and food safety, while UV+Matt lamination enables up to 24-month shelf life.

4.1. Main Technical Indicators (Standing Packaging Bag)

Standing Packaging Bag: Core Technical Data (2024 Edition)

| Property |

Performance |

Test Method/Standard |

| Thickness |

110 μm ± 10% |

ISO 4593 |

| Seal Strength |

>55 N/15mm |

ASTM F88 |

| OTR (Oxygen Transmission Rate) |

<2.1 cc/m2·24h |

ASTM D3985 |

| WVTR (Moisture Transmission) |

<0.8 g/m2·24h |

ASTM F1249 |

| Pouch Tolerance |

±0.3mm |

Company QC (ISO 9001) |

| Max Print Colors |

10 |

Rotogravure |

| Recycling Availability |

95% Film Types |

RecyClass |

*Data based on 2023–2024 Junlanpack batch tests; OTR

5. Industry Comparison: Top Stand Up Pouch Wholesale Suppliers

Comparison Table: Industry-Leading Stand Up Pouch Suppliers (2024)

| Supplier |

Main Market |

Key Strength |

Certifications |

MOQ (Bulk) |

Lead Time |

| Junlanpack |

Global |

Custom films, short lead, R&D |

FDA, ISO9001, SGS |

10,000 pcs |

12–16 days |

| ePac Flexibles |

USA/EU |

Digital print, low MOQ |

BRC, FDA |

5,000 pcs |

14–18 days |

| Amcor |

Global |

Sustainability leader |

FSSC22000, ISO |

30,000 pcs |

18–25 days |

| Huhtamaki |

EU/Asia |

Speciality pouches |

ISO, HACCP |

20,000 pcs |

16–22 days |

| Plastipak |

USA/EU |

Recyclable focus |

FDA, RecyClass |

10,000 pcs |

14–20 days |

6. Customization & End-Use Solutions

Standing Packaging Bag offers wide-ranging options for stand up pouch for sale in wholesale packaging:

- Material customizations (Mono PE, high-barrier EVOH, compostable PLA, Kraft + Window)

- Closure types: zip lock, side-gusset, slider, or spout fitments

- Sizing: from 40ml sample pouch to 5L bulk pouch

- Advanced printing: digital, tactile textures, gloss/matte

- Window design: clear/shape windows for FMCG visibility

- Compliance: food contact grade, BPA-free, ISO/FDA/SGS certified

Bulk Customization Process:

1. Customer submits artwork/specs

2. Engineering consults on film/closure

3. Free digital proofing & test run

4. Mass production with 100% QC

5. Global shipment with tracking

Average lead time: 12–16 days (bulk, 10,000+ units) after artwork approved.

Warranty: 18 months against manufacturing defects.

Case Example: Pet Food Brand Upgrade, US Midwest

- Required: 1.5kg zip-lock high-barrier pouch, 8-color print

- Delivered:

bulk stand up pouches with Kraft window, UV print, ISO22000-tested seals

- Results: 23% product freshness improvement (lab test), 19% sales increase in 6 months, zero leaks or odor complaints.

Customer Feedback: "Junlanpack's pouches gave our brand a premium shelf presence, with faster fulfillment than larger multinationals."

7. Typical Application Scenarios & Product Advantages

- Food & Snacks: Crisps, coffee beans, dried fruits, granola (barrier & resealability critical; tested under ISO 22000 & FDA compliance)

- Pet Food: Dry/wet formula, treats

- Industrial & Chemical: Powder, granule, and small part packaging; corrosion-resistant, anti-static (per ANSI/ISO specs)

- Pharmaceutical & Health: Medical herbs, sanitizers (sterile, non-leaching; ASTM F2096-tested seal integrity)

- Household & Personal Care: Detergents, masks, bath salts (child safety zips, UV-proof, tested for chemical compatibility in SGS labs)

8. Professional FAQ – Bulk Stand Up Pouches Terminology

Frequently Asked Questions

-

Q1: What is the difference between "OTR" and "WVTR"?

A: OTR means Oxygen Transmission Rate (measured in cc/m²·24h) and defines how much oxygen can permeate the pouch – vital for product freshness. WVTR is Moisture Vapor Transmission Rate (g/m²·24h); lower WVTR ensures prolonged product protection, especially for coffee, snacks, and pharmaceuticals.

-

Q2: What types of materials are most common for stand up pouch wholesale?

A: BOPP, PET, and PE film laminates are industry standards. For premium barrier, PET/AL/PE is used; for eco-friendly, Mono PE (approved by RecyClass and FDA).

-

Q3: What is the standard closure mechanism for stand up zip pouches wholesale?

A: Press-to-close zipper locks, slider zippers, and for spout pouches, screw caps. Welded zippers (ultrasonics) are specified for leak-proof performance per ISO 11607, and pass AQL 1.5 testing.

-

Q4: How is print quality ensured for bulk stand up pouches?

A: Multicolor gravure (8–10 colors with ≤0.25mm color registration per ISO 12647) or digital printing. All inks are low migration and FDA/SGS-certified.

-

Q5: What installation or filling standards do these pouches meet?

A: Standing Packaging Bag is compatible with form-fill-seal (FFS) machinery (CE, ANSI compliant), and auto-filling lines for powder/liquid; bottom gusset design supports shelf standing even after partial dispensing.

-

Q6: How long is the storage/shelf life of a bulk stand up pouch?

A: Up to 24 months with high-barrier constructions (OTR

-

Q7: What are the international standards for food contact safety?

A: All pouches comply with FDA CFR 21, EU 10/2011, and GB 9685. Each production batch is tested for heavy metals (SGS/Intertek) and migration indices.

9. Service & Support – EEAT Assurances

Industry Certification: Over 16 years experience, all products FDA, ISO9001, SGS, and HACCP certified.

Major Cooperations: Exported to P&G, Kraft Heinz, regional brands in over 60 countries.

Warranty: All bulk stand up pouches guaranteed against defects for 18 months.

After-Sales: Dedicated English-speaking support team (12h×6d coverage), trackable shipping, rapid claims resolution.

Customization: Free design/prototyping; NDA-protected confidential projects available.

Sample Policy: Free standard samples ship in 2 days.

10. References & Industry Resources

- MarketsandMarkets. (2023) Stand-up Pouch Market Report [link]

- Flexible Packaging Association: “State of Flexible Packaging Industry 2024” [link]

- Packaging Europe. “Barrier Properties for Stand-Up Pouches” [link]

- Food Packaging Forum: “Food Contact Regulations for Pouches” [link]

- ISO Technical Committees on Packaging [link]

- Material Science Journal: “Oxygen & Moisture Barrier Films for Flexible Packaging” [link]