In recent years, the demand for innovative and sustainable packaging solutions has surged, particularly in the food industry. Among the various sectors, the packaging for potato chips and similar snack products has garnered significant attention. This surge in interest is not arbitrary; it’s driven by an intricate blend of consumer demand, environmental considerations, and technological advancements. Understanding the materials used in chips packets is crucial not only from an environmental perspective but also for companies looking to optimize product quality and consumer satisfaction.

The conventional material historically employed for chips packets is a combination of plastic layers, often consisting of biaxially oriented polypropylene (BOPP) with a laminated aluminum foil layer. This combination offers an efficient barrier against oxygen, moisture, and light, ensuring the product remains fresh and crispy for extended periods. However, despite its effectiveness, traditional packaging materials have come under scrutiny due to environmental concerns. The non-biodegradable nature of such materials contributes to the burgeoning global issue of plastic waste.

A noteworthy shift is underway towards biodegradable and recyclable materials. Companies are exploring options like polylactic acid (PLA), a bioplastic derived from renewable resources such as corn starch or sugarcane. PLA is biodegradable under industrial composting conditions, offering a partial solution to the environmental challenges posed by conventional plastics. Similarly, some manufacturers are experimenting with cellophane, a cellulose-based material that is inherently biodegradable and has been used in food packaging for many years.

Yet, while these materials offer a more environmentally friendly profile, there’s an ongoing debate regarding their overall lifecycle sustainability. The production process for some bioplastics can be resource-intensive, raising questions about the trade-offs between using renewable materials and the energy expended in their production and disposal.

The expertise of material scientists and chemical engineers is pivotal in navigating these complex issues. These professionals are at the forefront of developing new composites that offer both environmental benefits and maintain, or even enhance, product protection. Ongoing research is focusing on combining natural fibers with bioplastics to improve resilience and functional properties such as barrier performance and printability, which are essential in food packaging.

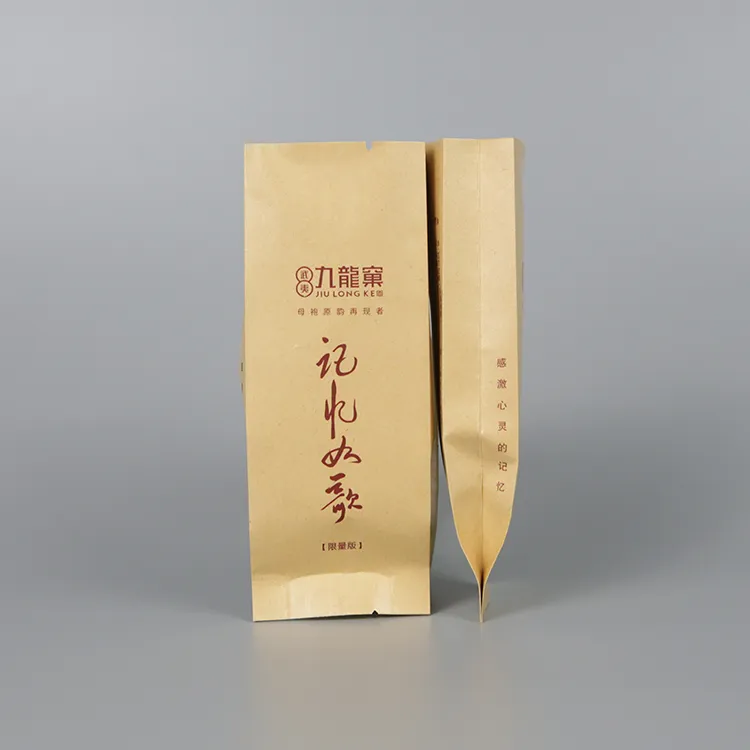

chips packet material

Authoritativeness in the chips packaging materials domain is further exemplified by policy changes and industry standards that are increasingly steering towards sustainable practices. Regulations in many regions now require companies to limit their reliance on non-recyclable and non-biodegradable materials. Adhering to these regulations is not just about compliance; it offers brands a chance to lead in an increasingly eco-conscious marketplace and establish significant trust with consumers who are making purchasing decisions influenced by sustainability factors.

Trustworthiness is also paramount. For a brand, building consumer trust involves transparent communication about the materials being used and their environmental impact. Brands that adopt credible eco-labels and certifications, such as the Forest Stewardship Council (FSC) for paper components or the Biodegradable Products Institute (BPI) certification for compostable materials, provide consumers with assurance about their commitment to sustainability.

Incorporating these strategies into a chips packet material initiative not only appeals to an audience increasingly concerned about environmental impact but also aligns with broader global efforts to move towards a circular economy in which materials are reused and recycled to a greater extent. This paradigm shift in packaging not only reflects a moral and ecological imperative but serves as a strategic advantage in an industry where differentiation is vital.

In conclusion, the exploration and implementation of innovative chips packet materials represent a dynamic intersection of experience, expertise, authoritativeness, and trustworthiness. By engaging in responsible practices and transparent communication, companies can not only contribute to reducing environmental footprints but also enhance brand loyalty and secure a competitive edge in the market. As the dialogue around sustainable packaging continues to evolve, staying abreast of advancements and understanding the implications of material choices will be key for any company invested in the future of food packaging.