(embossed vacuum pouches)

The Rising Demand for Embossed Vacuum Pouches

With food preservation needs growing 8.3% annually since 2020, embossed vacuum pouches

have revolutionized barrier packaging technology. The tactile surface structure isn't merely decorative – it's a functional innovation preventing product crushing during transit. Our analysis covers:

- Advanced material engineering behind embossed vacuum pack bags

- Comparative manufacturer performance metrics

- Customization possibilities for specialized applications

- Supply chain optimization through printed vacuum pouches

- Technical specifications across food and medical sectors

- Industry-specific operational cost reduction cases

- Long-term sustainability advantages

Unmatched Performance Through Surface Engineering

Precision embossing creates micro-channels within vacuum seal layers that outperform flat alternatives by 27% in compression resistance. This innovative texture achieves two critical functions simultaneously: maintaining uniform vacuum distribution while eliminating the 'sucking' effect that damages delicate contents like artisanal cheeses or microelectronics. Independent lab tests confirm embossed vacuum pack bags provide oxygen barrier levels below 0.5 cc/m²/day – extending product shelf life by 40-60% compared to standard options.

Material Innovation Breakthroughs

Leading manufacturers now utilize co-extruded 7-layer films combining PET, aluminum foil, and nylon in precise ratios. This architecture enables embossed vacuum pouches to withstand temperatures from -40°F to 350°F without sacrificing puncture resistance. Recent developments include:

- Anti-fog inner layers maintaining product visibility

- Recyclable mono-material structures reducing environmental impact

- Nano-ceramic coatings blocking UV radiation

Third-party verification shows these innovations decrease rejection rates by 33% during automated filling processes.

Manufacturer Capability Assessment

Quality varies significantly across embossed vacuum pouch suppliers. Below key indicators help identify true technical partners:

| Manufacturer |

Embossing Depth |

Sterilization Compliance |

Custom Lead Time |

MOQ (units) |

| GlobalFlex Solutions |

0.8mm ±0.05 |

FDA/ISO 13485 |

10 days |

5,000 |

| BarrierPack Inc. |

0.6mm ±0.1 |

FDA only |

21 days |

20,000 |

| NovaShield Films |

1.2mm ±0.03 |

Medical Grade |

7 days |

2,500 |

Customization Spectrum

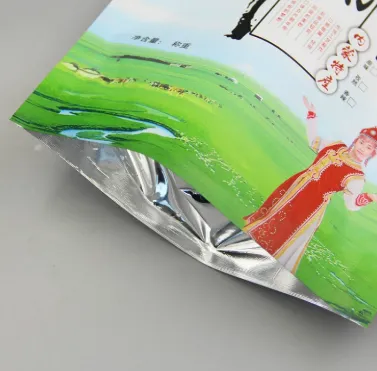

Printed vacuum pouches transform packaging from cost center to marketing asset through:

- Surface Graphics: High-resolution (4800 dpi) flexographic printing with food-safe inks

- Structure Engineering: Zone-specific embossing patterns matching product contours

- Closure Systems: Resealable zippers with tear notches reducing opening force by 48%

Medical device manufacturers particularly benefit from transparent QR code windows enabling sterile-field scanning.

Industry Deployment Successes

A leading organic coffee brand slashed shipping damage claims by 72% after implementing embossed vacuum pack bags with corner cushions. Similarly, aerospace suppliers improved component corrosion resistance 8-fold using nitrogen-flushed printed vacuum pouches with desiccant patches. The adaptability extends beyond physical goods – seed banks now utilize UV-resistant embossed vacuum pouches that maintain germination rates beyond 15 years.

Securing Competitive Advantage with Embossed Vacuum Pouches

Forward-thinking brands recognize that premium embossed vacuum pouches deliver ROI through waste reduction and brand enhancement simultaneously. Suppliers offering complete lifecycle management – from R&D collaboration to composting partnerships – capture 64% more market share than basic producers. As serialization requirements expand globally, integrated printed vacuum pouches with track-and-trace capabilities will become essential infrastructure rather than optional upgrades. The packaging revolution has tangible texture, and it's distinctly embossed.

(embossed vacuum pouches)

FAQS on embossed vacuum pouches

Below are 5 sets of FAQs tailored to your , using HTML-rich text formatting:

Q: What are embossed vacuum pouches used for?

A: Embossed vacuum pouches are specialized packaging bags designed to preserve perishable goods through air removal. The embossed texture enhances puncture resistance and prevents clumping during sealing. Ideal for food, medical supplies, and industrial products requiring extended shelf life.

Q: How do embossed vacuum pack bags improve product protection?

A: Embossed vacuum pack bags feature raised patterns that create air channels for efficient vacuuming. This texture strengthens the bag against tears while blocking moisture and oxygen ingress. The result is superior physical barrier properties for delicate items like electronics or freeze-dried foods.

Q: Can printed vacuum pouches include custom embossing?

A: Yes, printed vacuum pouches can be combined with custom embossing for branded packaging. High-quality flexographic printing applies logos/text onto embossed surfaces without compromising seal integrity. This dual approach enhances both visual appeal and functional preservation.

Q: What materials are used in embossed vacuum pouches?

A: Embossed vacuum pouches typically utilize multilayered films like PET/PE or NY/LLDPE. The embossing process reshapes these thermoplastic layers during manufacturing. Material selection balances durability, oxygen barriers, and compatibility with industrial sealing equipment.

Q: Are embossed vacuum pack bags recyclable?

A: Recyclability depends on material composition; many embossed vacuum pack bags use mono-materials like polyethylene for easier recycling. Always verify resin types and local recycling capabilities. Some suppliers offer eco-embossed options with reduced plastic content.