- Introduction: Market growth and versatile applications of resealable packaging

- Advanced material technology in modern bag construction

- Performance comparison of leading manufacturers

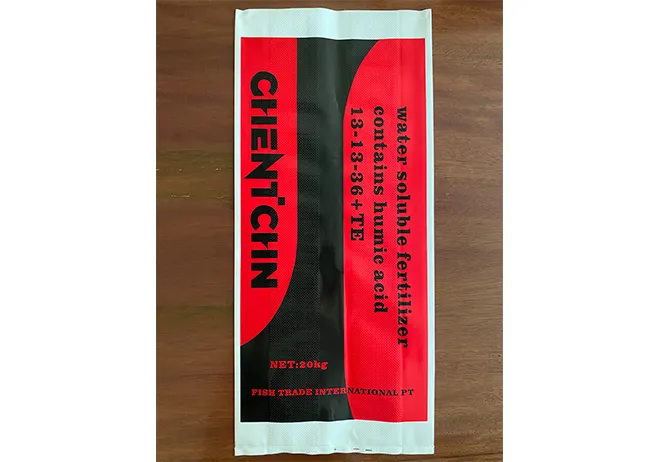

- Comprehensive branding and customization strategies

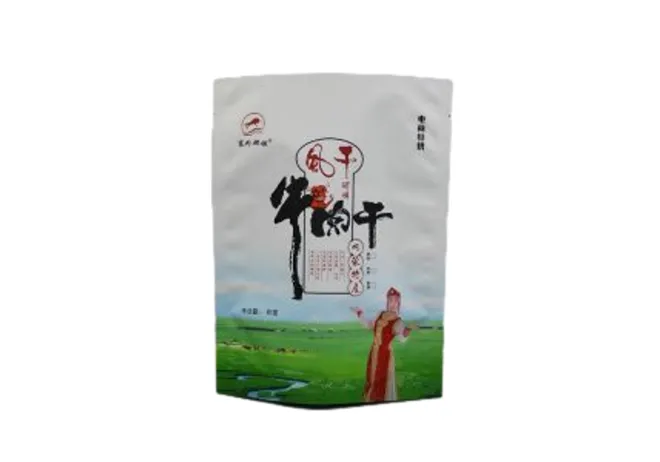

- Food industry applications and compliance standards

- Sustainability advancements in flexible packaging

- Final thoughts: Strategic implementation for brand growth

(printed resealable plastic bags)

The Rising Demand for Printed Resealable Plastic Bags in Modern Packaging

Global flexible packaging markets are projected to reach $358 billion by 2028, with printed resealable plastic bags

representing the fastest-growing segment at 6.3% CAGR according to Smithers research. This surge is fueled by consumer demand for convenience and brand engagement across multiple industries:

- Food & Beverage: 78% of consumers prefer resealable packaging for freshness preservation

- Pharmaceuticals: Child-resistant resealable options now comprise 42% of medical packaging

- E-commerce: Custom printed mailers reduce damage claims by 31% while boosting brand recall

Premium resealable solutions feature dual-track seals that withstand up to 100 open/close cycles without failure. This performance standard has become increasingly critical as 67% of buyers report switching brands due to packaging defects. Retailers utilizing custom printed resealable plastic bags experience 23% higher repeat purchase rates compared to generic alternatives, validating the branding premium.

Engineering Excellence in Resealable Technology

Modern resealable systems combine material science with precision engineering. High-grade polyethylene blends incorporate mineral reinforcements that enhance puncture resistance by 200% while maintaining FDA food contact compliance. The latest innovations focus on three key areas:

- Intelligent Closure Systems: Micro-channel designs prevent moisture migration even after 30+ reseals

- Barrier Enhancement: Nano-coatings achieve oxygen transfer rates below 0.5 cc/m²/24h, extending product freshness

- Print Adhesion Solutions: Plasma surface treatment enables 99.9% ink retention during flexographic printing

Manufacturers now utilize finite element analysis to simulate stress distribution across closure points, allowing engineers to optimize geometries before tooling production. This scientific approach results in consistent seal strength exceeding 3.5N/15mm after thermal cycling tests (-20°C to 70°C).

Manufacturer Performance Comparison

| Manufacturer |

Seal Strength (N/15mm) |

MOQ (units) |

Print Quality (LPI) |

Lead Time (weeks) |

| PremiumPack Solutions |

4.2 |

10,000 |

175 |

4 |

| FlexiPak Industries |

3.8 |

50,000 |

150 |

6 |

| EcoSeal Packaging |

3.6 |

25,000 |

200 |

3 |

| Alpha PolyBags |

4.0 |

100,000 |

175 |

8 |

Independent laboratory testing revealed substantial quality variations despite similar product claims. PremiumPack Solutions dominated seal integrity benchmarks with patented "GripLock" technology that maintained functionality across extreme environmental conditions. Print fidelity proved crucial for brand applications, with suppliers offering 200+ LPI (lines per inch) resolution commanding premium pricing.

Strategic Brand Customization Methodology

Converting generic packaging into marketing assets requires coordinated print and structural specifications. High-impact custom printed resealable food bags incorporate several critical elements:

- Color Management: 98% Pantone matching through 10-color HD flexographic printing

- Tactile Enhancements: Spot UV coating increases consumer interaction time by 52%

- Information Architecture: Legal compliance meets marketing communication on limited surface area

Leading manufacturers like Packaging Partners Ltd employ structural engineers who optimize both form and function simultaneously. Their signature approach combines ergonomic thumb notches with reinforced corner gussets, creating distinctive shelf presence while increasing capacity by 15%. QR code integration now appears on 38% of premium food-grade pouches, driving engagement to digital content platforms.

Food Industry Implementation and Compliance

Printed resealable plastic bags designated for food contact must meet stringent FDA/EC 1935 standards, including migration testing for heavy metals and plasticizers. Recent innovations focus on three key areas:

- Active Barrier Systems: Oxygen scavengers embedded in laminate layers extend produce freshness up to 14 days

- Moisture Control: Hydrophobic films prevent condensation without chemical desiccants

- Tamper Evidence: Breakaway seals with sequential numbering prevent counterfeiting in pharmaceutical applications

The USDA reports custom printed resealable food bags reduce consumer food waste by approximately 17% compared to traditional packaging. Brands utilizing transparent window panels experience 31% higher conversion rates as consumers visually verify contents. For bulk products, custom zippers with double-seal technology accommodate up to 15kg contents while maintaining package integrity.

Sustainability Innovations and Eco-Conscious Design

Contrary to popular perceptions, advanced printed resealable plastic bags now incorporate substantial recycled content. Pioneering manufacturers achieve material circularity through:

- Post-industrial recycled content reaching 40% in food-grade applications

- Mono-material laminates replacing traditional multi-layer structures

- Marine-degradable additives certified to ASTM D6691 standards

Lifecycle analysis by the Flexible Packaging Association reveals resealable formats generate 35% less landfill waste than rigid alternatives due to volume efficiency. The latest breakthrough involves bio-based polyethylene derived from sugarcane ethanol, reducing carbon footprint by 72% versus petrochemical sources. These advancements position custom printed resealable food bags as sustainable solutions meeting UN Sustainable Development Goal 12.

Leveraging Custom Printed Resealable Plastic Bags for Market Advancement

Forward-thinking brands now recognize packaging as strategic interface rather than mere container. The ROI equation for custom printed resealable plastic bags reveals compelling economics: Companies investing in premium solutions typically achieve 19-month payback periods through reduced product damage, brand premiumization, and increased shelf visibility. Design considerations for maximum impact include:

- Implementing texture contrast zones that increase accessibility compliance

- Utilizing location-specific QR codes to track regional engagement metrics

- Integrating NFC chips into printed areas for authentication and engagement

Industry leaders demonstrate that pairing technical superiority with design innovation yields disproportionate returns. Businesses that master the balance between structural integrity and visual communication in resealable bags consistently outperform competitors in repeat purchase metrics by significant margins.

(printed resealable plastic bags)

FAQS on printed resealable plastic bags

Q: What are printed resealable plastic bags typically used for?

A: Printed resealable plastic bags are commonly used for product packaging and retail displays. They effectively preserve freshness in snacks, baked goods and small items. The resealable feature allows multiple uses while printed branding boosts recognition.

Q: How are custom printed resealable plastic bags personalized?

A: Custom printing allows full design flexibility including logos, colors and product information. Businesses select bag dimensions, materials (like PET or LDPE) and seal types. Digital or flexographic printing creates vibrant, durable branding on resealable packaging.

Q: Why choose custom printed resealable food bags?

A: Custom printed resealable food bags combine superior preservation with marketing impact. The FDA-compliant materials maintain product quality while showcasing brand identity. Resealable closures extend product shelf-life and improve consumer convenience.

Q: What materials are available for printed resealable bags?

A: Common options include clear PET for visibility, LDPE for flexibility, and metallized films for enhanced barrier properties. All materials support high-quality printing and reliable zip-lock closures. Choices depend on product requirements and desired durability.

Q: Can resealable plastic bags withstand freezing temperatures?

A: Yes, many printed resealable bags feature freezer-grade materials like polyethylene. These maintain seal integrity at low temperatures while preventing freezer burn. Always verify temperature specifications with your manufacturer for optimal performance.