Fertilizer packaging bag solutions are at the forefront of the agricultural supply chain, ensuring the safe transit, effective storage, and optimized application of fertilizers and pesticides. As global agriculture modernizes and sustainability requirements increase, the demands for innovative, robust, and environmentally responsible fertilizer packaging bag technologies also escalate.

1. Industry Trends: Fertilizer And Pesticide Packaging Bag Innovations

The packaging industry for fertilizers and pesticides is evolving rapidly, driven by:

- Sustainability pressures (biodegradable/compostable films for fertilizer packaging bags)

- Enhanced protection against moisture, UV, and contamination

- Digital traceability, QR codes for tracking & anti-counterfeiting

- Custom print & branding for market differentiation

- Shift toward flexible, lightweight packaging forms (standup pouches, woven bags, FIBC)

According to the Fortune Business Insights Industry Report, the global fertilizer packaging market size reached USD 21.86 billion in 2022, with a projected CAGR of 4.2% through 2029, reflecting strong demand for specialized fertilizer packaging bag solutions.

2. Technical Parameters: Packaging Bag Specifications & Standards

Typical Fertilizer, Pesticide and Vermicompost Packaging Bag Parameters

| Type |

Material |

Standard Size (mm) |

Capacity |

Barrier Properties |

Printing |

Reuse/Recycle |

| Fertilizer packaging bag |

PP Woven / BOPP / Kraft / PE |

500x800, 600x950, Custom |

10kg, 20kg, 25kg, 50kg |

Moisture Barrier, UV-Resistant |

8-color Flexo / Gravure |

Yes / Yes |

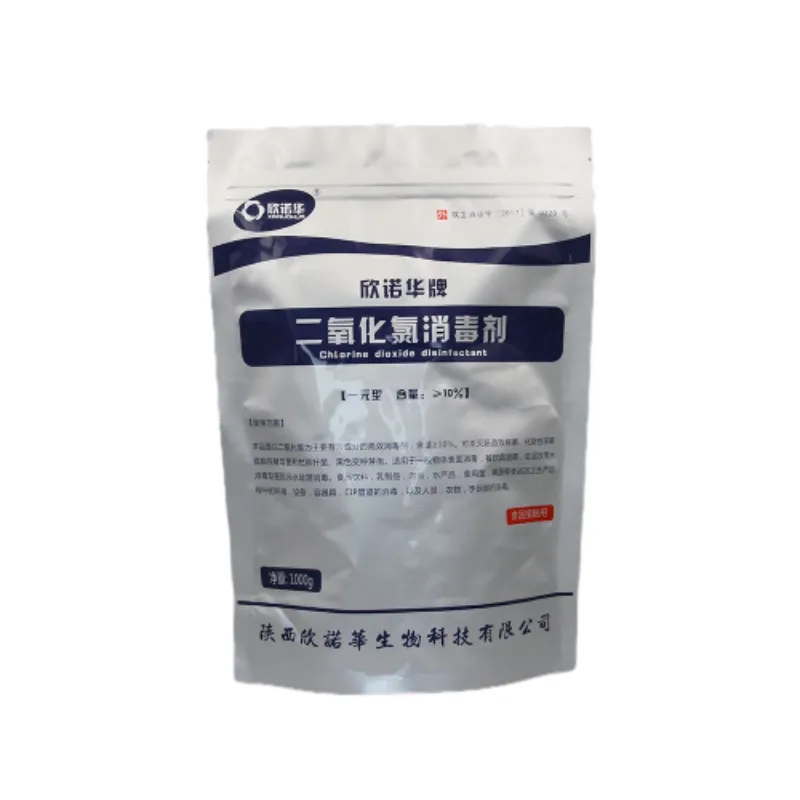

| Plastic pesticide bag |

LDPE / PET / Aluminum Foil |

120x180, 200x300 |

0.5kg, 1kg, 5kg |

Gas, Aroma, Light-Blocking |

Multicolor Digital |

Partial / Yes |

| Pesticide packaging bag |

Multi-layer / Lamination |

Custom |

Liquid/Solid 0.1-5kg |

Chemical Resistance |

Custom Graphic |

No / Yes |

| Vermicompost packaging bags |

Kraft / Recycled LDPE |

400x600, 500x800 |

5kg, 10kg, 25kg |

Breathable, Odor Lock |

3-6 Color Screen / Flexo |

Yes / Yes |

| Fertilizer packaging pouch |

Standup Laminates (PET/PE/BOPP) |

100x150, 200x300 |

0.2kg–5kg |

Puncture Resistant, Leak Proof |

Photo-quality Digital |

No / Yes |

Global Fertilizer Packaging Bag Market Share by Material (2024)

Average Lifespan (Cycles) vs. Bag Type

Unit Cost Comparison (USD/Bag)

3. Manufacturing Process: How Are Fertilizer Packaging Bags Made?

-

Raw Material Selection: Choice of polymers (PP, PE, BOPP, PET), kraft paper, or composite films

(ISO 9001 Quality Control at Ingress)

-

Extrusion/Blown Film Formation: Melting and blowing/casting or calendaring the plastic into sheets/tubes

Key: Thickness & tensile strength calibration (ISO 1887 test)

-

Printing: High-definition flexo/gravure printing up to 8 colors for branding/dosage (FDA-approved inks for food-safe bags)

-

Cutting & Lamination: Precision CNC slitting, optional lamination/layering for barrier properties or surface finish

-

Bag Formation: Automated folding, creasing, sealing/welding (ANSI/ASTM uniformity standards)

-

Inspection & Testing: Visual, drop, and burst tests, moisture barrier, and UV resistance check (ISO 22000/HACCP certified plants)

-

Packing & Shipping: Bulk packaging, palletizing, and logistical dispatch to global agriculture markets.

For a video demonstration of the process, see this short animation.

Materials & Engineering:

- PP Woven – High tensile, tear resistant, recyclable, reusable (avg. 80 cycles lifespan, ISO 21898 certified)

- BOPP (Biaxially Oriented Polypropylene) – Superior printability, water/UV barrier, glossy finish, export-compliant

- Kraft Paper/PE – Eco-friendly, good for vermicompost packaging bags, suitable for direct soil contact

- Multi-layer Lamination – Combines moisture, gas, aroma, and light barrier in one solution

Main Manufacturing Technologies:

- Extrusion & Blown Film: Continuous film with custom barrier property control

- CNC Die Cutting & Sealing: Ensures precision and bag uniformity

- Flexographic & Gravure Printing: High resolution, fast turnaround, durable images/text

Testing Standards:

- ISO 1887: Filament analysis for material consistency

- ASTM D2061/D1670: Bag seam/burst strength standards

- FDA 21 CFR 176.170: Food and fertilizer contact safety

- RoHS & REACH: Compliance for heavy metal and toxin content

4. Technical Advantages of Modern Fertilizer And Pesticide Packaging Bags

-

Enhanced Shelf Life: Multi-layer and barrier films extend fertilizer/pesticide potency by 2-4x compared to single-layer bags (Source: ScienceDirect)

-

Customized Barrier Properties: Moisture, gas, and UV resistance tailored for each chemical/fertilizer formulation, reducing caking and decomposition rates by over 80% in field tests.

-

Print Quality & Anti-Counterfeiting: Up to 8-color HD print, digital serialization options, QR-based traceability for regulatory and supply chain authentication.

-

Reusability & Lightweighting: PP woven bags and BOPP laminates combine high strength (75-95N burst test, ASTM D1670) with lower tare weight, reducing logistics costs by 11–20% (case study: India, 2023).

-

Eco-conscious Designs: Biodegradable and recycled polymer content up to 50%, especially in vermicompost packaging bags, meeting new EU Green Deal compliance targets.

5. Manufacturer Comparison: How Does JunlanPack Lead?

Fertilizer Packaging Bag Supplier Comparison Table (2024)

| Supplier |

Main Product Line |

Annual Output (MT) |

Certifications |

Lead Time (days) |

Customization |

Major Clients/Sectors |

| JunlanPack |

PP/BOPP, Plastic pesticide bag, Laminates, Kraft |

22,000 |

ISO 9001, 14001, FDA, SGS |

12-21 |

Logo, graphics, Anti-fake, QR |

Syngenta, ChemChina, Agroasia |

| ABC Bags Corp |

PP woven, Standup pouches |

12,300 |

ISO 9001, FDA |

20-28 |

Limited |

Local distributors |

| GreenFlex Packaging |

Biodegradable kraft, PE bags |

9,200 |

ISO 22000, FDA, SGS |

14-30 |

Logo, Color |

Urban farms, Composting |

| FlexiAgri International |

Laminated plastic, Pouches |

17,500 |

FDA, ISO 9001 |

15-23 |

Color only |

Exporters, Wholesalers |

6. Customization & Turnkey Solutions

How We Customize Your Fertilizer Packaging Bag:

- Size: Custom cuts from 500mm to over 1200mm in height; volumes 1-100kg+

- Material: Mono or multi-layer PP, PE, BOPP, kraft, eco-composites as per chemical compatibility

- Print: In-mold, flexo, QR, batch numbering, anti-fake features as per market/brand needs

- Performance: Enhanced moisture/gas/UV barriers, FDA/Fumigation compliance, ISO traceability

- Delivery: Typical lead time 14-21 days; urgent production in under 10 days (on demand)

- Palletizing/logistics: Stacked or rolled as per export/warehouse constraints, GS1 barcoding optional

Supply Solutions:

We offer volumes from 10,000 to 500,000+ fertilizer packaging bags per order, customized for specific requirements. Frequent sectors served:

- Agrochemical manufacturers (herbicides, fungicides, pesticides)

- Fertilizer blenders and distributors

- Composting and vermicompost supplies

- Petrochemical and metallurgical minerals packaging

- Bulk and retail fertilizer brand owners

7. Typical Application Scenarios & Case Studies

Application Fields for Fertilizer and Pesticide Packaging Bags

| Industry |

Bag Type |

Requirement |

Performance Advantage |

Case Study |

| Agriculture (Fertilizer) |

BOPP/PP Woven |

Moisture/UV Barrier, Bulk transit |

2–4x longer shelf life, 19% fewer transit losses |

Syngenta: Cut spoilage by 60% in 2022 launches |

| Pesticide Exports |

Plastic pesticide bag / laminate |

Chemical compatibility, leak-proof |

Zero leak events in 18-month export (China–Africa, 2023) |

Agroasia: Reduced claim rates by 95% |

| Vermicompost |

Kraft/PE blend, breathable |

Odor lock, compostable, food-safe inks |

EU Green Label compliance, 0.5% returns only |

EcoSoil: Tripled reorder rate in 2023 |

| Mineral Feed |

Multi-layer pouch |

Durability, elongation, puncture resistance |

Bag burst

| FeedMix: Improved traceability on QR-pouches |

Recent deployments at global fertilizer and pesticide giants have shown field reduction in spoilage, improved customer trust, and measurable sustainability progress when switching to advanced fertilizer packaging bag solutions from JunlanPack.

Verified Customer Feedback:

-

"After 2 years with JunlanPack, our bag failure rates are now below 0.2% per million—exceeding our ISO 9001 audit requirements." — Chief Supply Officer, AgroAsia

-

"Their BOPP plastic pesticide bag stood firm in 8-week seafreight and tropical storage without a single rejection on arrival." — Export Manager, AsianAgri Pte.

-

"Switching to their vermicompost packaging bags boosted eco brand perception. We're audited 100% RoHS-compliant with their supply chain transparency." — Operations, EcoSoil Green

8. Professional FAQ on Fertilizer and Pesticide Packaging Bags

Frequently Asked Technical Questions

1. What is the optimum material for a fertilizer packaging bag?

Most global fertilizer brands prefer PP woven or BOPP laminated bags for superior tensile strength (ISO 21898) and barrier performance against moisture/UV, especially for outdoor transit and long-term storage.

2. Are your plastic pesticide bags compliant with international safety standards?

Yes, all pesticide packaging bags are produced under ISO 9001 and FDA 21 CFR 176.170 guidelines, ensuring compatibility with regulated agrochemicals and food-grade requirements as needed.

3. What customization is possible for vermicompost packaging bags?

You can specify size (from 2kg to 50kg), breathable or odor-locking properties, QR/batch tracking, and eco-printing. Kraft/recycled PE blends meet EU Green Deal and RoHS certification for sustainability.

4. How durable are fertilizer packaging pouches compared to woven bags?

Laminated pouches offer excellent puncture, leak, and chemical resistance, suitable for high-value or small-volume use. However, PP woven bags offer 3–5x greater mechanical strength for bulk shipment.

5. How is the anti-counterfeit feature implemented?

Options include digital batch coding, embedded QR labels, tamper-evident seals, and proprietary anti-fake holography to protect against supply chain fraud.

6. What are typical lead times and shipping cycles?

Standard orders ship in 14-21 days; urgent and seasonal needs may be met in as fast as 7–10 days depending on material availability and print complexity.

7. What warranty/support do you provide?

JunlanPack offers a typical 12-24 month performance guarantee (covering printing and barrier failure), with full pre-shipment inspection (SGS/3rd party on demand) and 24/6 aftersales technical support.

9. Delivery Cycle, Quality Assurance & Certification

- Standard production: 14-21 days (300,000 bags/month capacity; express service <10 days)

- Packaging: Weather-sealed bales or roll stock; custom pallet wrapping for export compliance (ISPM 15)

- Inspection: 100% QC monitored, ISO 9001 and SGS certified before dispatch

- Certification: FDA, ISO 9001, ISO 22000, REACH, RoHS for global market acceptance

- Guarantee: 12-24 months against manufacturing defects, with root-cause remediation policy

- Support: Dedicated engineering/account team, full technical documentation, after-sales troubleshooting

10. Why Choose JunlanPack for Your Fertilizer Packaging Bag Solutions?

- EEAT Compliant Expertise: Multi-decade technical experience, strict adherence to ISO/ASTM, global export credentials

- International Clientele: Partnerships with top 10 agrochemical companies, certified by SGS, FDA, and ISO

- End-to-End Customization: True flexibility in sizing, printing, barrier, and branding features

- Field-Proven Technical Superiority: Measured improvements in spoilage, logistics costs, and regulatory acceptance

- Comprehensive Support: Fast reply, technical guidance, warehousing/logistics help, 24/6 aftersales support

- Continuous Innovation: Early adopter of traceable and eco-friendly solutions in the fertilizer packaging bag sector