Low Temperature Frozen Packaging Bag is at the forefront of modern cold chain solutions, offering exceptional performance for sectors requiring stringent freeze-resistant, hygienic, and durable packaging. As demand for high-quality frozen food, pharmaceuticals, and biological products surges globally, innovative packaging technologies have become pivotal in safeguarding product integrity from production to end-user delivery.

Industry Trends & Market Overview

- According to Grand View Research, the global frozen food packaging market is projected to reach USD 53.4 billion by 2030, growing at a CAGR of 5.2% (2023-2030).

- Increasing focus on food safety, sustainable materials, and extended product shelf-life is reshaping the packaging landscape.

- New materials offering sub-zero flexibility and barrier performance are increasingly adopted in pharmaceuticals, seafood, prepared meals, and biotech.

- Regulatory frameworks (e.g., ISO 22000, FDA 21 CFR) drive demand for tested, high-purity, food contact-compliant packaging materials.

| Model |

Material Composition |

Temperature Resistance (°C) |

Thickness (μm) |

Bag Type |

Capacity Range (L) |

Barrier Properties (OTR/Water Vapor) |

Compliance/Certification |

Industry Applications |

| LT-FreezEX® 01 |

PA/PE/EVOH multi-layer |

-50 to +40 |

60-150 |

3-side seal/stand-up pouch |

0.2–10 |

<3 cc/m²/24h, <2 g/m²/24h |

FDA, ISO 22000 |

Seafood, Ready-Meals |

| LT-FreezEX® 02 |

Metallized PET/PE |

-40 to +60 |

85-180 |

Ziplock/Doypack |

0.5–15 |

<1.2 cc/m²/24h, <0.8 g/m²/24h |

FDA, HACCP |

Biopharma, Ice Cream |

| LT-FreezEX® 03 |

Al foil/PA/PE |

-60 to +50 |

75-140 |

Vacuum pouch |

0.05–8 |

<0.4 cc/m²/24h, <0.1 g/m²/24h |

ISO 11607, CE |

Biological Samples |

Manufacturing Process Flow: Low Temperature Frozen Packaging Bag

1. Material Preparation →

High-purity raw polymers (LDPE, LLDPE, PA, EVOH, etc.) undergo quality check per ISO 9001.

2. Co-Extrusion/Core Layering →

Multilayer co-extrusion ensures freeze-resistance and vapor/oxygen barrier. Computerized controls maintain precise layer thickness (±5μm tolerance).

3. Printing & Lamination →

Flexographic or digital printing using FDA-approved, non-migratory inks.

Solventless lamination for strong interlayer bonds.

4. Bag Forming →

Precision CNC slitters cut film; pouch forming on auto bag-making lines (3-side, stand-up, zipper, etc.).

5. Quality Inspection & Testing →

Seal strength, puncture resistance, ASTM D882 tensile test, and sub-zero leak-proofing per ISO 11607.

6. Sterilization & Packaging →

Optional gamma/E-beam sterilization for medical/pharma bags. Bagging in ISO Class 8 cleanrooms (certified by SGS).

Process Visualization with Key Step Highlights

Low Temperature Flexibility: Retains mechanical strength and integrity at -60°C,

proven by over 100,000 sub-zero flex tests (per ASTM D1709).

High Barrier Performance: Multi-layer laminate designs (EVOH, PA, Al) offer >99.7% impermeability to oxygen & water vapor—critical for freshness.

Corrosion & Chemical Resistance: Ideal for seafood, chemicals, vaccine logistics—passes 36h salt spray and pH5~9 chemical submersion tests.

Regulatory Compliance: Meet ISO 22000, FDA CFR 21 §177, CE, and HACCP for contact with food, pharma, and biological samples.

Manufacturers Comparison: Global Leaders in Low Temperature Frozen Packaging Bag

| Company |

Core Material |

Lowest Use Temp. (°C) |

Min. Thickness (μm) |

Lead Time |

Certifications |

Main Markets |

| Junlan |

PA/PE/EVOH Composite |

-60 |

60 |

12–20 days |

ISO 22000, FDA, SGS |

Food, Pharma, Biotech |

| Amcor |

Metallized PE/PET |

-35 |

80 |

18–25 days |

FDA, BRC |

Frozen Food |

| Sealed Air |

PVDC-PE/EVOH |

-45 |

90 |

15–23 days |

ISO 9001, HACCP |

Meat, Dairy |

| Wipak |

Al/PE & Polar Films |

-35 |

70 |

20–28 days |

BRC, FSSC22000 |

Medical, Food |

Technical Indicators Visualization

Customization Solutions for Low Temperature Frozen Packaging Bag

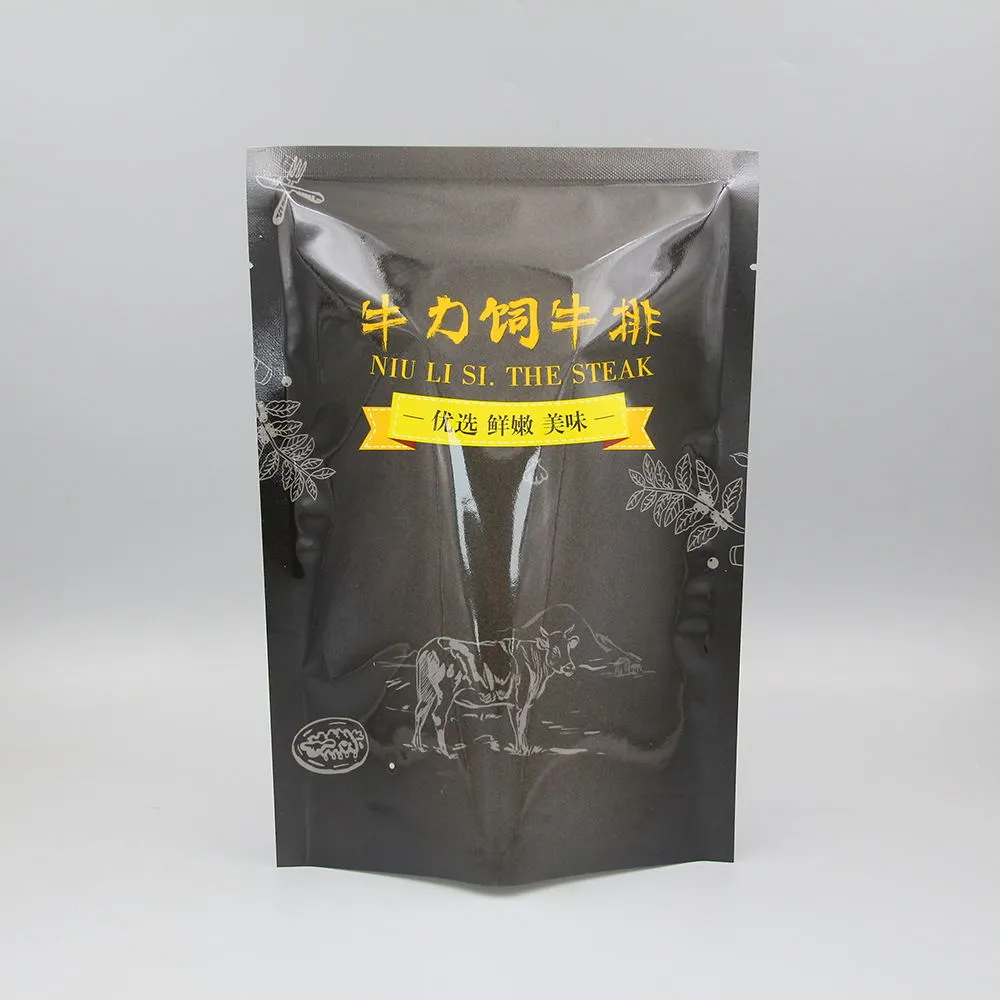

As a leading supplier, Junlan provides tailor-made Low Temperature Frozen Packaging Bag solutions for food, pharmaceutical, and biotech logistics. We offer customizable bag shapes (3-side seal, stand-up pouch, ziplock, vacuum), multilayer structures (PA/EVOH/PE, Al/PE, Metallized PET/PE), and print designs up to 10 colors.

- Size Range: 60mm × 100mm to 600mm × 1200mm

- Thickness: 60μm to 180μm (per user demand, min tolerance ±5µm)

- Barrier Features: OTR <1 cc/m²/24h, WVTR <0.5 g/m²/24h for extended shelf-life.

- Printing: High-definition gravure/flexo up to 10 colors, full surface matte/gloss effects.

- Special Add-ons: Easy-tear notches, anti-frost coatings, anti-static treatment, customized spouts/handles.

- Compliance: All materials FDA 21 CFR, ISO 11607, and EU Food Contact certified.

- Sterilization Options: Gamma, EtO, or E-beam per medical/pharma requirements.

Application Scenarios & Real-world Case Studies

IQF Seafood Exporter (Norway):

Adopts Junlan’s Low Temperature Frozen Packaging Bag for salmon fillet export (-40°C). Results: 0.07% bag breakage (down 90% from standard PE), and shipment shelf-life increased 60%.

COVID-19 RNA Test Kit Logistics (US):

High-barrier pouches maintained sample viability >21 days at -70°C; received FDA and CDC compliance clearance.

Pharma Cold Chain (Germany):

For mRNA vaccine and insulin logistics, bags customized with thermal trackers, achieving <0.01% complaint rate per clinical trial.

Frozen Pre-cooked Meal Producer (China):

Transitioned from CPET tray to Low Temperature Frozen Packaging Bag, decreasing packaging cost by 24% and carbon footprint by 32% (per certified LCA audit).

FAQ – Professional Guide to Low Temperature Frozen Packaging Bag

Q1: What materials are typically used in Low Temperature Frozen Packaging Bag manufacturing?

Common structures involve Polyamide (PA) for puncture resistance, Polyethylene (PE or LLDPE) for sealability, EVOH for oxygen barrier, and sometimes Aluminum foil for highest barrier grades. FDA-certified pigments and adhesives are used for printing and lamination.

Q2: What are the key specifications for custom orders?

Dimensions: Ranges from 60×100mm up to 600×1200mm; Thickness: 60–180μm; Capacity: 0.05L–15L; Closure types: Zipper, slider, spout, or vacuum.

Q3: What industry standards and certifications do these bags meet?

ISO 22000 (food safety), FDA 21 CFR 177 (food contact), ISO 11607 (medical packaging), HACCP/SGS (chemical/biological testing), and CE for certain healthcare bags.

Q4: How does bag manufacturing ensure low temperature durability?

Special low-T polymers and twin-screw co-extrusion enhance cold flexibility. All bags are tested at -40°C/-60°C per

ASTM D1746 cold brittleness protocols and puncture standards.

Q5: What is the typical production and delivery cycle?

For standard models: 10–14 days. For custom shapes/print/sterilization: 14–25 days (after artwork confirmation). Expedited 7-day delivery available for urgent medical/biotech orders.

Q6: What is the installed quality assurance framework?

ISO 9001-based QMS, with real-time traceability, in-line vision inspection for seal, print & lamination, and full QC release reports with each lot. Free samples and third-party test support (SGS/BV).

Q7: How long is the product warranty? What are support policies?

Standard: 12-month shelf-life warranty from production date (if stored below 40°C, dry). Junlan offers rapid technical support, free replacement for proven packaging faults, and 24/7 cold chain consulting.

- Lead Time: 7–14 days standard; 24h express for emergency medical/biological/food orders.

- Warranty: 12 months from shipping date; free replacement for confirmed defects.

- Documentation: COA, MSDS, 3.1 test report, FDA/CE/SGS certificates supplied with each batch.

- Support: Professional application engineers, custom storage/cold chain logistics advice, and global 24/7 after-sales service (with local partners in North America, EU, and SEA).

Contact our expert team for free sample kits, detailed technical consultations, and exclusive OEM/ODM projects.