In the ever-evolving world of packaging, efficiency, sustainability, and brand appeal are paramount. The Flat Pocket, a cornerstone of modern flexible packaging, has emerged as a superior solution for a vast array of industries. This comprehensive guide explores the technology behind the Flat Pocket, its numerous applications, and how Junlanpack’s expertise delivers unparalleled quality and customization. Our commitment to excellence is built on years of experience, authoritative industry certifications, and the trust of our global clientele.

Junlanpack offers a diverse range of fully customizable Flat Pocket solutions.

Industry Trends: The Rise of Flexible and Sustainable Packaging

The global packaging market is undergoing a significant transformation. A recent market analysis highlights a decisive shift away from rigid container111s towards flexible alternatives. According to a report by Grand View Research, the global flexible packaging market is projected to reach USD 390.2 billion by 2030, expanding at a CAGR of 4.5%. This growth is driven by several key factors where the Flat Pocket excels:

- Sustainability: Brands and consumers are increasingly demanding eco-friendly options. Flat Pockets use significantly less material than rigid counterparts, reducing raw material consumption and carbon footprint during transport. Recyclable and compostable material options are becoming industry standards.

- E-commerce Boom: The surge in online shopping requires packaging that is lightweight, durable, and space-efficient to minimize shipping costs and prevent damage. The slim profile of a Flat Pocket is ideal for this purpose.

- Consumer Convenience: Features like tear notches, resealable zippers, and easy-to-handle designs enhance the user experience, a critical factor in consumer loyalty.

- Brand Differentiation: High-quality printing on a Flat Pocket provides a large, flat canvas for vibrant graphics and compelling branding, helping products stand out on crowded shelves.

Vibrant branding on a Flat Pocket captures consumer attention.

Flexible Packaging Market Growth (USD Billion)

The Anatomy of a Flat Pocket: A Deep Dive into Technology and Materials

A Flat Pocket, also known as a flat pouch or three-side seal pouch, is a highly versatile packaging format sealed on three sides, leaving one side open for filling. Its true strength lies in the advanced material science and precision manufacturing processes that create a durable, protective, and visually appealing package. Our expertise in material selection and lamination ensures optimal performance for every unique application.

Material Composition: The Science of Protection

The performance of a Flat Pocket is determined by its multi-layered structure. Each layer serves a specific purpose, and the combination is engineered to meet precise product requirements. Common materials include:

- PET (Polyethylene Terephthalate): Provides a high-gloss, scratch-resistant outer layer perfect for printing. It also offers excellent tensile strength and thermal stability.

- AL (Aluminum Foil): The ultimate barrier layer, offering near-perfect protection against oxygen, moisture, light, and aroma. Essential for sensitive products like coffee, pharmaceuticals, and certain food items. Its inclusion is critical for meeting stringent shelf-life requirements.

- NY (Nylon / PA): Adds puncture resistance and flexibility, crucial for packaging products with sharp edges or for vacuum-sealing applications.

- PE (Polyethylene) / CPP (Cast Polypropylene): The innermost layer, serving as the food-contact and sealing surface. It must be compliant with food-grade standards like those set by the FDA and provide a strong, reliable hermetic seal.

Technical Specifications Overview

At Junlanpack, we adhere to strict international standards. Our Flat Pockets are rigorously tested to ensure they meet the highest quality benchmarks. Below is a table of typical technical parameters.

| Parameter |

Specification / Standard |

Benefit & Importance |

| Material Structure |

Customized (e.g., PET/AL/PE, PET/VMPET/PE, PET/PE) |

Engineered for specific product protection needs (barrier, strength). |

| Thickness |

50 - 200 microns (2 - 8 mil) |

Balances durability with material usage and cost-effectiveness. |

| Oxygen Transmission Rate (OTR) |

< 0.1 cc/100in²/24hr (for high-barrier) |

Prevents oxidation, preserving product freshness, color, and flavor. Measured per ASTM D3985. |

| Water Vapor Transmission Rate (WVTR) |

< 0.1 g/100in²/24hr (for high-barrier) |

Prevents moisture ingress or loss, protecting texture and preventing spoilage. Measured per ASTM F1249. |

| Seal Strength |

> 35 N/15mm |

Ensures pouch integrity during shipping and handling, preventing leaks. |

| Food Safety Compliance |

FDA, EU 10/2011 |

Guarantees that materials are safe for direct contact with food products. |

| Certifications |

ISO 9001:2015, BRCGS |

Demonstrates commitment to a globally recognized quality management system and packaging safety. |

The Manufacturing Process: From Raw Material to Finished Flat Pocket

Creating a high-quality Flat Pocket is a multi-stage process that demands precision engineering and stringent quality control at every step. Our state-of-the-art facility, certified under ISO 9001, ensures consistency and excellence.

🔬

1. Material Selection & Lamination

Based on product needs, select and laminate multiple film layers to create a composite material with the desired barrier and structural properties.

→

🎨

2. High-Definition Printing

Using up to 10-color rotogravure presses, your custom graphics are printed onto the outer film layer with exceptional clarity and vibrancy.

→

✂️

3. Pouch Forming & Sealing

The printed, laminated film is precisely cut and heat-sealed on three sides by automated pouch-making machines to form the final Flat Pocket.

→

⚙️

4. Feature Integration

Custom features like resealable zippers, tear notches for easy opening, and hang holes for retail display are added during the forming stage.

→

✅

5. Quality Control & Testing

Finished pouches undergo rigorous testing for seal integrity (burst test), dimensions, and print quality before being approved for shipping.

This meticulous process ensures that every Flat Pocket we produce not only looks great but also provides the superior protection your product deserves. Our experience allows us to fine-tune each step to optimize for performance and cost-efficiency.

Precision printing is a critical step in creating a premium Flat Pocket.

Technical Advantages & Manufacturer Comparison

Choosing Junlanpack for your Flat Pocket needs means choosing a partner dedicated to superior quality and performance. Compared to standard industry offerings or traditional rigid packaging, our solutions provide tangible benefits.

Junlanpack Flat Pocket vs. Standard Pouch Performance

| Feature |

Junlanpack Flat Pocket |

Standard Industry Pouches |

| Barrier Performance (OTR/WVTR) |

✔ High (Custom-engineered multi-layer films) |

Variable (Often generic, lower-grade films) |

| Material Quality & Sourcing |

✔ Premium, traceable, FDA-compliant materials |

Inconsistent sourcing, may lack full compliance |

| Printing Technology |

✔ HD Rotogravure (Up to 10 colors) |

Standard Flexo or lower-resolution printing |

| Customization Options |

✔ Fully customizable (size, shape, features, finish) |

✖ Limited to standard sizes and features |

| Quality Certifications |

✔ ISO 9001, BRCGS |

Often uncertified |

| Expert Consultation |

✔ Dedicated packaging specialist for every project |

✖ Limited to sales representative interaction |

Endless Possibilities: Customization & Application Scenarios

The true power of the Flat Pocket lies in its versatility. We don't just sell pouches; we create tailored packaging solutions. Our experience spans dozens of industries, and we understand the unique challenges each one presents.

Your Vision, Our Expertise: Full Customization

- Custom Sizing: From small sample packs to large bulk bags, we produce Flat Pockets in any dimension you require.

- Material Engineering: We'll design the perfect film structure for your product, whether you need ultra-high barriers, puncture resistance, or recyclability.

- Printing & Finishes: Make your brand pop with matte, gloss, or combination finishes, metallic effects, and spot UV treatments.

- Functional Features: Enhance consumer convenience with press-to-close zippers, child-resistant locks, laser scoring, tear notches, and euro or round hang holes.

A custom Flat Pocket for snacks, showcasing brand identity and product appeal.

Application Case Study: Artisan Coffee Roaster

"Switching to Junlanpack's custom-printed Flat Pockets was a game-changer. The aluminum foil layer keeps our beans incredibly fresh, extending shelf life by 40%. The high-quality printing elevated our brand, and customers love the resealable zipper. Our online sales increased by 25% within three months of the packaging redesign. The experience and support from their team were invaluable."

Specialty coffee packaging requires a high-barrier Flat Pocket.

Diverse Industry Applications

Our Flat Pockets are trusted by brands in numerous sectors:

- Food & Beverage: Coffee, tea, snacks, spices, powdered mixes, sauces.

- Pet Food: Dry kibble, treats, supplements.

- Health & Beauty: Face masks, lotions, bath salts, cosmetics.

- Pharmaceutical & Nutraceutical: Pills, supplements, powders.

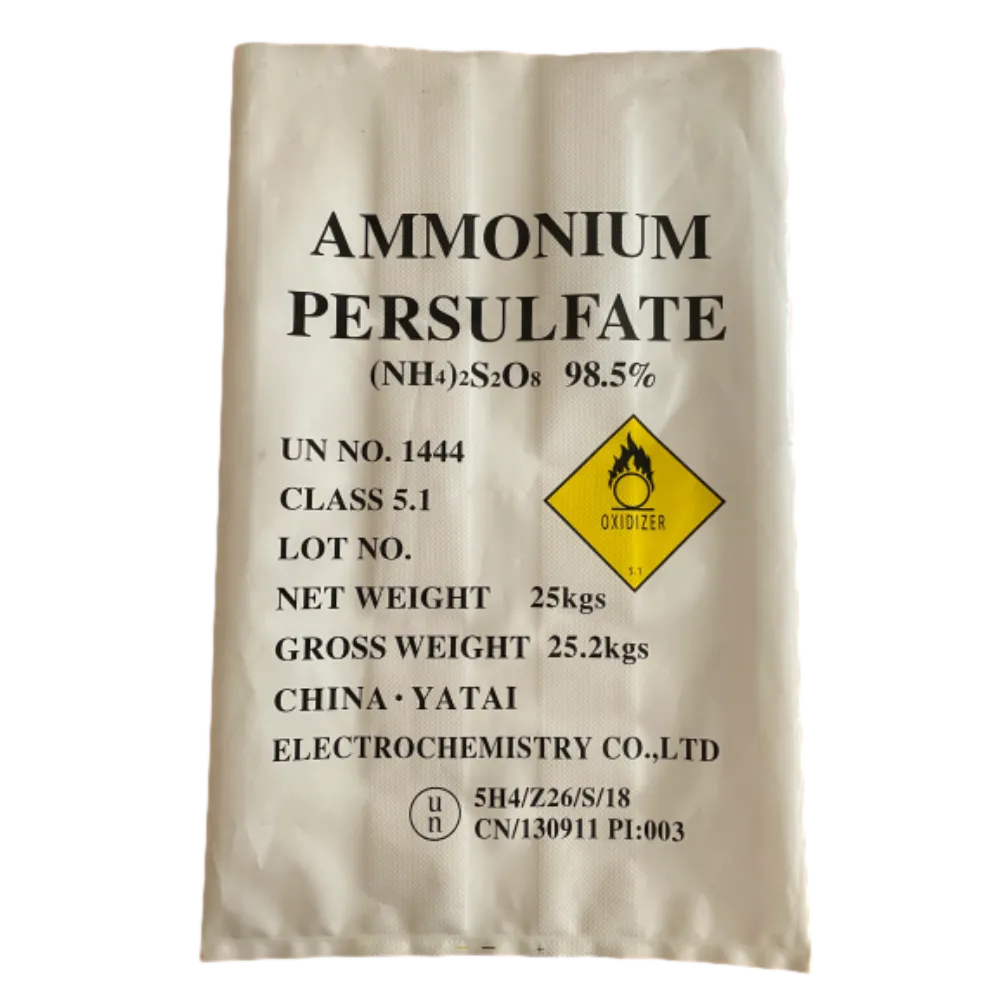

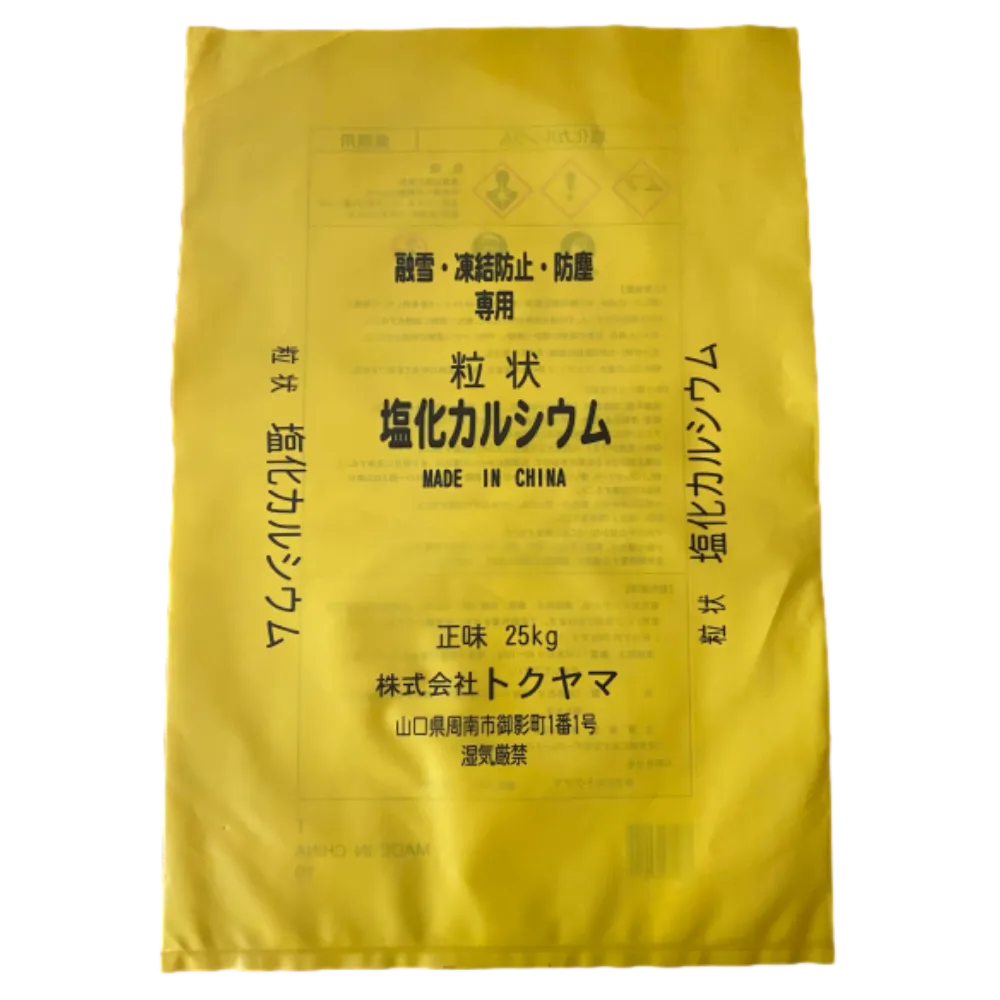

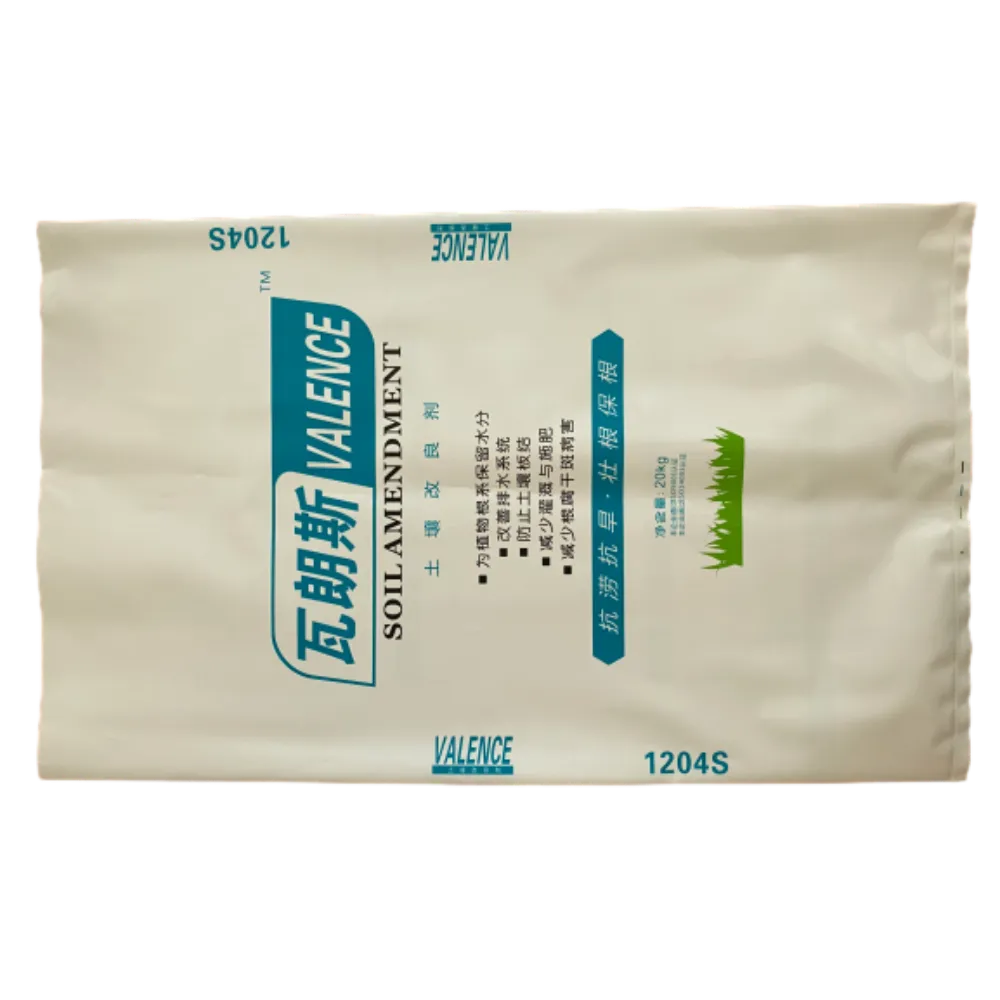

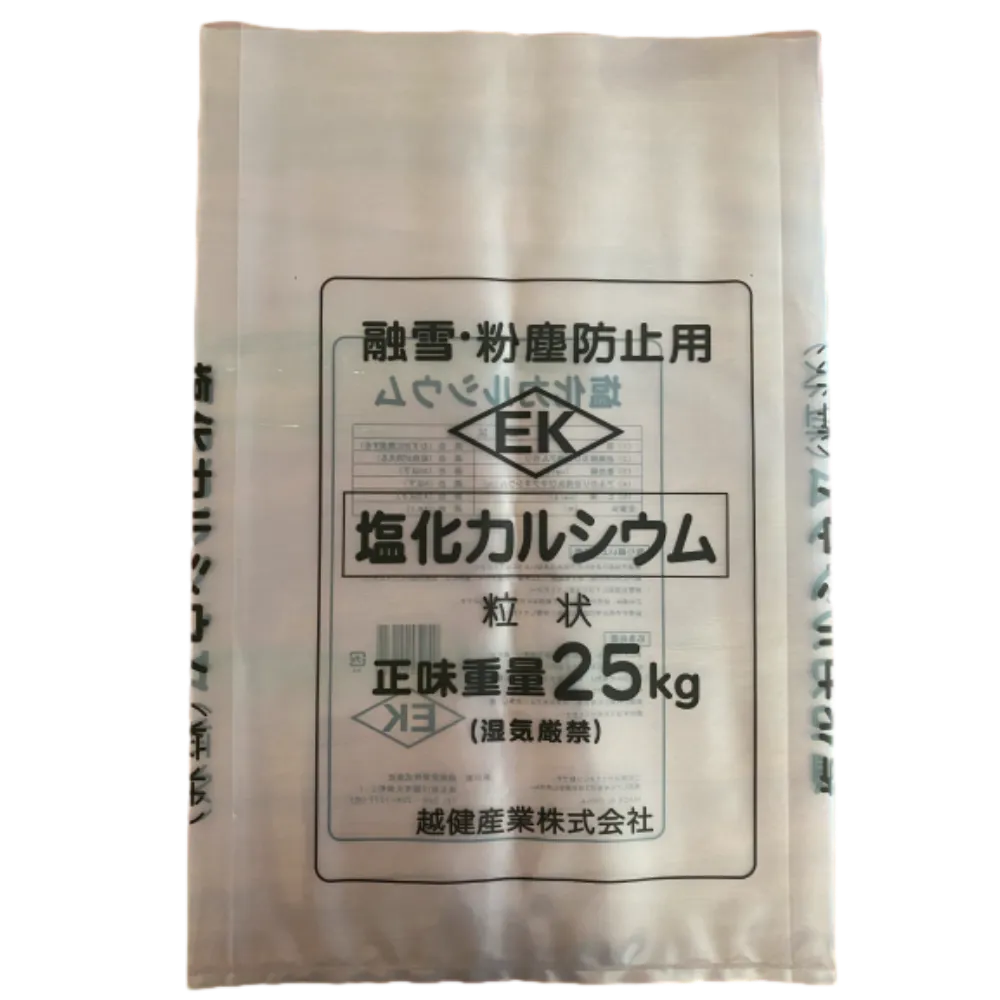

- Industrial & Household: Detergents, seeds, small parts, chemicals.

Flat Pocket Application Market Share

Building Trust: Quality Assurance, Certifications, and Support

Trust is the foundation of any successful partnership. We earn your trust through demonstrable expertise, authoritative certifications, and an unwavering commitment to quality. Our business is built on transparency and reliability.

Every Flat Pocket undergoes rigorous quality assurance checks.

- Authoritative Certifications: Our manufacturing facilities are certified against the highest global standards, including ISO 9001:2015 for quality management and BRCGS for packaging safety. Our materials are FDA-compliant for direct food contact.

- Quality Guarantee: We stand behind every Flat Pocket we produce. Our multi-point quality control process ensures that your packaging meets or exceeds the agreed-upon specifications. We offer a comprehensive quality guarantee and a clear process for addressing any concerns.

- Transparent Process: From initial quote to final delivery, we keep you informed. Typical lead times for custom orders range from 4-6 weeks after artwork approval. We provide a detailed timeline and regular updates.

- Dedicated Customer Support: Our team of packaging experts is here to support you. We provide consultation on material selection, design optimization, and logistics to ensure a smooth and successful project.

Frequently Asked Questions (FAQ)

1. What materials are used for your Flat Pockets, and are they food-safe?

Absolutely. We use a variety of multi-layer laminated films, typically combinations of PET, PE, CPP, Nylon, and Aluminum Foil. All food-contact layers are made from virgin, FDA-compliant resins (like PE or CPP), ensuring they are completely safe for packaging food products. We provide compliance documentation upon request.

2. What is the minimum order quantity (MOQ) for custom-printed Flat Pockets?

Our MOQ typically starts at 10,000 pieces per design. This quantity allows us to optimize our rotogravure printing press setup and manufacturing runs, providing you with the best possible price per unit. However, the exact MOQ can vary based on pouch size and material complexity, so please contact us for a specific quote.

3. What is the difference between Rotogravure and Digital printing?

We specialize in Rotogravure printing, which uses engraved metal cylinders to transfer ink. This method is ideal for high-volume runs (like our MOQ) and delivers superior, photo-realistic print quality, vibrant colors, and consistency across the entire batch. Digital printing is better suited for very small runs or prototypes but generally cannot match the quality and cost-effectiveness of rotogravure at scale.

4. How do I choose the right barrier properties (OTR/WVTR) for my product?

Our experts will guide you. The required barrier depends on your product's sensitivity to oxygen and moisture. For example:

- High-Barrier (with Aluminum Foil): For coffee, nuts, and sensitive medical products that require maximum shelf life.

- Medium-Barrier (with Metallized PET): For snacks like chips or cookies.

- Low-Barrier (Clear films): For products with a short shelf life or those not sensitive to atmospheric conditions, like some hardware or apparel items.

We will recommend the most cost-effective structure that meets your product's shelf-life requirements.

5. Can you help with the design and artwork for my Flat Pocket?

While we require print-ready artwork from our clients, our experienced pre-press team can provide critical support. We supply detailed artwork templates (dielines) and guidelines. We will review your submitted artwork to ensure it meets all technical requirements for printing, such as color separation, resolution, and bleed, to guarantee a perfect final product.

6. What is the typical lead time for a custom order?

The standard lead time is approximately 4-6 weeks from the date of final artwork approval and order confirmation. This timeline includes cylinder production (for rotogravure printing), material lamination, printing, pouch converting, and quality control. We provide a more precise timeline with your formal quotation.

7. Are your Flat Pockets recyclable?

We are committed to sustainability and offer recyclable Flat Pocket options. These are typically made from a mono-material structure (e.g., all-PE), which makes them eligible for store drop-off recycling programs. Please specify your interest in recyclable packaging during your initial consultation so we can engineer the appropriate material structure for you.

Authoritative References & Further Reading

Our commitment to expertise is rooted in continuous learning and adherence to industry best practices. For those interested in a deeper dive, we recommend the following authoritative sources:

- Robertson, G. L. (2013). Food Packaging: Principles and Practice (3rd ed.). CRC Press. - An academic textbook covering the science of packaging materials and their interaction with food products. View on Routledge

- "The State of the Flexible Packaging Industry Report" by the Flexible Packaging Association (FPA). Provides annual data, trends, and analysis on the North American market. Visit FPA Website

- Packaging World Magazine - An industry-leading publication covering innovations, technologies, and trends in all forms of packaging. Explore Flexible Packaging Section