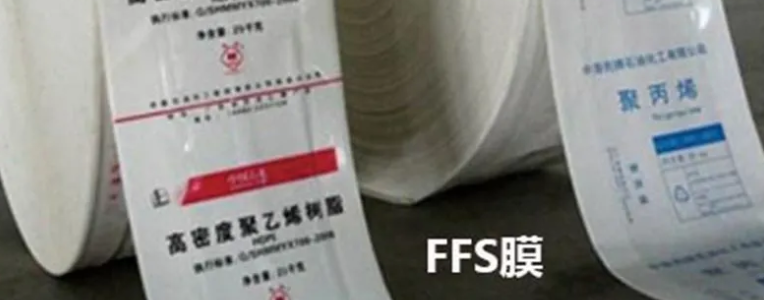

FFS bags manufacturing process overview encompasses a series of precision-engineered steps that go beyond standard bag production, addressing the unique demands of heavy-duty packaging for granular and powdered materials. Xiongxian Junlan Paper Plastic Packaging Co., Ltd. specializes in optimizing this process to meet industry-specific needs, and FFS heavy-duty packaging is usually used to carry solid particles or powdered materials weighing 10-50 kilograms, with 25 kilogram packaging being the most common, hence also known as 25 kilogram bags. Our expertise in material science and automated production ensures pelikula ng ffs, ffs bags, at ffs film para sa mga pinong kemikal meet rigorous standards for strength, barrier performance, and compatibility with diverse filling systems—critical for applications ranging from construction aggregates to high-purity fine chemicals.

Film Extrusion Precision in Ffs film

- Layer Thickness Uniformity: Ffs film extrusion uses a co-rotating twin-screw extruder with 8 temperature zones (160-230°C), ensuring each layer (PE, EVOH, PP) has a thickness tolerance of ±0.5μm. This uniformity is critical for consistent barrier performance, as tested in our lab via laser thickness gauges that scan the film at 1000 points/second.

- Additive Masterbatch Integration: Ffs film for heavy-duty use incorporates UV stabilizers (0.5% concentration) and anti-blocking agents (1% silica) during extrusion, mixed via a precision feeder that controls dosage to ±0.1%. This prevents film degradation in outdoor storage and ensures smooth unwinding during bag formation.

- Orientation Optimization: Ffs film undergoes biaxial orientation (MD: 3x stretch, TD: 4x stretch) to enhance tensile strength by 40%, making it suitable for 50kg load-bearing. Our orientation frames use servo motors for precise stretch control, avoiding film distortion that could weaken the final bag.

Bag Formation Specialization in Ffs bags

- Bottom Seal Reinforcement: Ffs bags feature a 3-layer bottom seal (15mm width) created via ultrasonic welding, which increases seal strength to 800 N/15mm—30% higher than heat-sealed alternatives. This reinforcement prevents bottom rupture during filling of dense materials like sand or cement.

- Valve Integration Accuracy: Ffs bags with filling valves (for powdered materials) have valve openings aligned to within ±1mm of the bag’s centerline, ensuring seamless connection to filling nozzles. Our vision inspection system verifies valve position before sealing, reducing filling errors by 95%.

- Gusset Formation Control: Ffs bags with side gussets use a mechanical folding system that maintains a gusset width tolerance of ±2mm, ensuring the bag expands uniformly during filling. This prevents uneven material distribution that could cause the bag to tip during transport.

Chemical Compatibility in Ffs film for fine chemicals

- Acid and Alkali Resistance: Ffs film for fine chemicals uses a 20μm LDPE layer modified with ethylene-acrylic acid (EAA) copolymer, resisting permeation of 10% sulfuric acid and 20% sodium hydroxide by 94%. This is tested in our lab via 1000-hour immersion tests without film degradation.

- Low Extractable Content: Ffs film for fine chemicals undergoes a solvent extraction process (per FDA 21 CFR §177) that reduces extractable compounds to <5 ppm, critical for high-purity chemicals like pharmaceutical intermediates. Our gas chromatography tests confirm no contamination of the packaged product.

- Static Dissipation: Ffs film for fine chemicals incorporates carbon black additives (2% concentration) to achieve a surface resistance of 10⁶-10⁸ ohms, preventing static buildup that could ignite flammable powders. This meets NFPA 77 standards for static control in chemical packaging.

Quality Control Integration in Ffs bags

- In-Line Leak Detection: Ffs bags undergo 100% leak testing via vacuum decay technology, which detects leaks as small as 5μm in 0.5 seconds. This ensures no material seepage during transport, a critical requirement for hazardous fine chemicals.

- Tensile Strength Sampling: Every 100th ffs bags is tested for tensile strength (MD: ≥25 MPa, TD: ≥20 MPa) and elongation at break (≥300%), with data logged in our quality management system. This sampling frequency ensures consistent performance across production batches.

- Barrier Performance Validation: Ffs bags for moisture-sensitive chemicals are tested for WVTR (<0.1 g/100in²/day) and OTR (<0.2 cc/100in²/day) post-production, using our permeation analyzers to confirm compliance with customer specifications. Any non-conforming bags are automatically diverted from the production line.

|

Manufacturing Stage

|

Key Process Parameter

|

Ffs film Specification

|

Ffs bags Specification

|

Ffs film for fine chemicals Specification

|

|

Extrusion

|

Layer Thickness Tolerance

|

±0.5μm

|

N/A

|

±0.3μm (higher precision for chemicals)

|

|

Bag Formation

|

Seal Strength

|

N/A

|

800 N/15mm (bottom seal)

|

900 N/15mm (chemical-resistant seal)

|

|

Additive Integration

|

UV Stabilizer Dosage

|

0.5%

|

0.5%

|

0.5% + 2% carbon black (static control)

|

|

Quality Control

|

Leak Detection Sensitivity

|

N/A

|

5μm leak detection

|

3μm leak detection (higher sensitivity)

|

|

Barrier Testing

|

WVTR (g/100in²/day)

|

<0.15

|

<0.15

|

<0.10 (moisture-sensitive chemicals)

|

FFS bags FAQS

How does the manufacturing process of ffs film ensure compatibility with 50kg loads?

Ffs film undergoes biaxial orientation (MD: 3x, TD: 4x) during extrusion, which enhances tensile strength by 40% to ≥25 MPa. Our twin-screw extruder also ensures uniform layer thickness, preventing weak points that could fail under heavy loads—tests confirm the film withstands 50kg tension for 1000+ hours without tearing.

What makes ffs bags suitable for automated filling systems?

Ffs bags have precise dimensional tolerances (±2mm for width/height) and centered filling valves (±1mm alignment), ensuring seamless integration with automated filling lines. The bottom seal reinforcement (800 N/15mm) also handles the pressure of high-speed filling (50 bags/minute) without rupture.

How is ffs film for fine chemicals tested for chemical compatibility?

Ffs film for fine chemicals undergoes 1000-hour immersion tests in target chemicals (e.g., acids, solvents) and is analyzed via GC-MS to detect extractables. Our lab also tests film integrity post-immersion, ensuring no swelling, cracking, or barrier degradation that could contaminate the chemical.

Can ffs bags be customized for specific filling speeds?

Yes, ffs bags are customized by adjusting seal strength (600-1000 N/15mm) and film thickness (50-150μm) based on filling speed. For high-speed lines (60 bags/minute), we use thicker films (120μm) and ultrasonic seals; for low-speed lines (20 bags/minute), thinner films (80μm) with heat seals suffice—all tailored to customer equipment.

How does the manufacturing process of ffs film prevent static buildup for fine chemicals?

Ffs film for fine chemicals has carbon black additives (2% concentration) mixed during extrusion, creating a conductive network that reduces surface resistance to 10⁶-10⁸ ohms. Our in-line static testing ensures uniform additive distribution, preventing static hotspots that could pose risks for flammable powders.