- Overview of poly bag packaging and its industrial significance

- Material innovations driving performance improvements

- Comparative analysis of leading packaging manufacturers

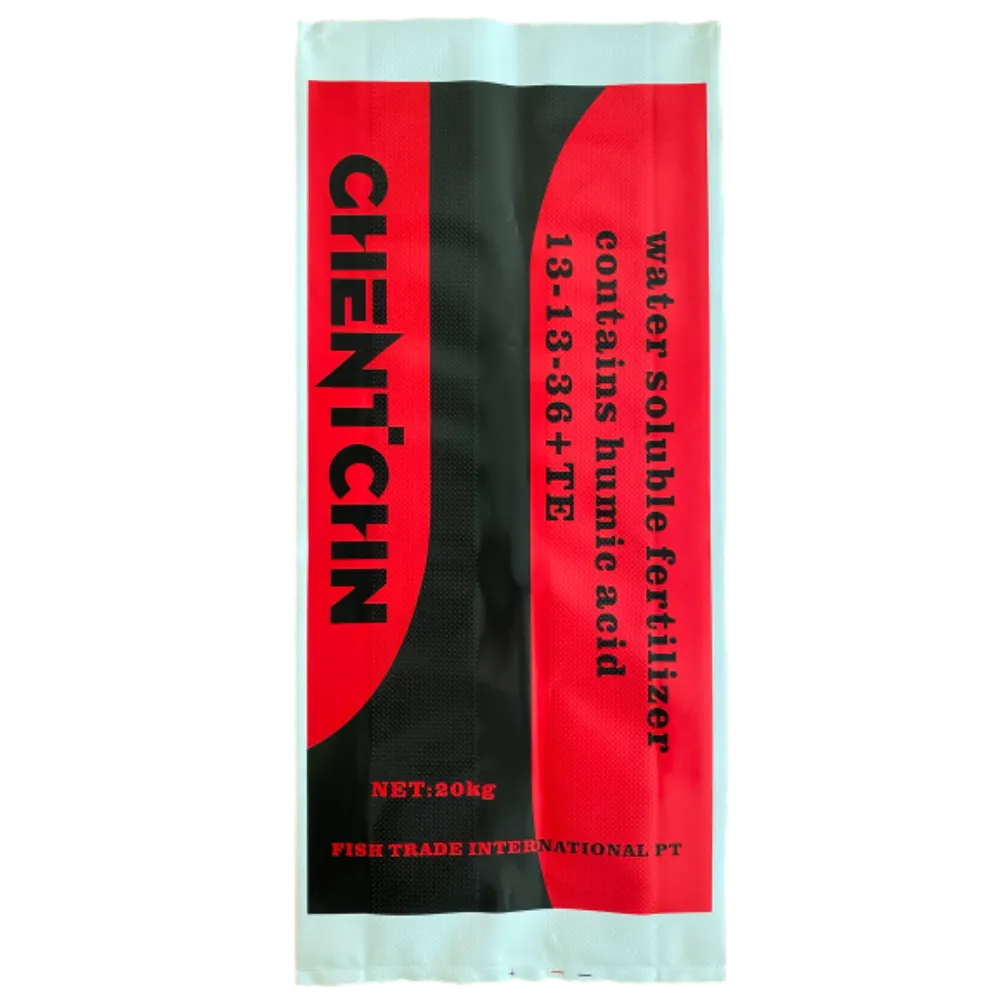

- Customization strategies for diverse business needs

- Real-world applications across key industries

- Sustainability trends in flexible packaging solutions

- Future outlook for bag packaging types

(types of bag packaging)

Understanding Types of Poly Bag Packaging in Modern Industry

The global poly bag packaging market, valued at $18.3 billion in 2023 (Grand View Research), has evolved beyond basic containment solutions. Three primary material categories dominate industrial applications:

- Polyethylene (PE): 62% market share, ideal for retail and food packaging

- Polypropylene (PP): 28% adoption rate, preferred for medical and pharmaceutical uses

- Biodegradable polymers: 10% annual growth, driven by EU packaging regulations

Recent advancements in co-extrusion technology enable 15-20% stronger seals while reducing material thickness by 18%, addressing both cost and sustainability concerns.

Technical Superiority in Material Engineering

High-performance resins now achieve:

- UV resistance exceeding 2,000 hours (ASTM G154)

- Puncture resistance up to 6.5 N/mm² (ISO 6383-2)

- Temperature tolerance from -50°C to 120°C

Manufacturers like Dow Chemical have developed hybrid films combining PE and nylon layers, enhancing moisture barrier properties by 40% compared to standard options.

Manufacturer Capability Comparison

| Vendor | Price Range | Material Specialization | MOQ | Key Advantage |

|---|

| Amcor | $0.08-$0.35/unit | Multi-layer laminates | 50,000 units | FDA-compliant food packaging |

| Berry Global | $0.12-$0.42/unit | Recycled PE | 25,000 units | 75% post-consumer material |

| Sealed Air | $0.15-$0.60/unit | Anti-static films | 10,000 units | ESD protection for electronics |

Tailored Packaging Solutions

Customization parameters include:

- Thickness variations (1.5-6 mil)

- Printing options: Flexographic (≤8 colors) vs Digital (full CMYK)

- Closure systems: Zipper (≥5mm width), Slider, or Heat Seal

Industrial users report 23% faster production line speeds when using pre-perforated bags with machine-direction orientation.

Cross-Industry Implementation Cases

Food Sector: Modified atmosphere packaging extends produce shelf life by 5-8 days through 0.5-2% oxygen permeability.

Healthcare: Class VI-certified bags withstand ethylene oxide sterilization cycles (55°C, 60% RH).

E-commerce: Anti-abrasion mailers reduce damage claims by 18% in parcel shipping.

Eco-Friendly Material Transition

The industry is shifting toward:

- PLA-based compostable bags (90% degradation in 12 weeks)

- Water-soluble PVOH films for detergent packaging

- PCR content up to 50% without tensile strength loss

California’s SB 54 legislation mandates 30% PCR content in all flexible packaging by 2028, accelerating material innovation.

Strategic Development in Bag Packaging Types

The packaging bag types market is projected to reach $24.1 billion by 2028, driven by:

- Automated packaging systems requiring precision-cut bags

- Blockchain integration for supply chain transparency

- Active packaging with oxygen scavengers/antimicrobial agents

Leading converters now offer 72-hour prototyping services, enabling rapid response to market demands while maintaining 1.5mm±0.2mm dimensional accuracy.

(types of bag packaging)

FAQS on types of bag packaging

Q: What are the common types of poly bag packaging?

A: Common types include flat poly bags, gusseted poly bags, resealable zipper bags, anti-static poly bags, and garment bags. These are widely used for retail, industrial, and food packaging due to their flexibility and durability.

Q: What distinguishes different types of bag packaging materials?

A: Materials like polyethylene (LDPE, HDPE), polypropylene, biodegradable plastics, and compostable films define bag types. Each offers unique properties, such as moisture resistance, strength, or eco-friendliness, for specific applications.

Q: How do resealable poly bags differ from standard poly bags?

A: Resealable poly bags feature integrated zipper closures for repeated access, while standard poly bags are sealed once. They are ideal for perishables or reusable items, unlike single-use flat bags.

Q: What are the primary uses of gusseted packaging bags?

A: Gusseted bags have expandable sides for bulkier items like powders, grains, or textiles. They maximize storage space and stability, making them popular in food, agriculture, and retail industries.

Q: Which packaging bag types are eco-friendly alternatives?

A: Compostable bags, biodegradable poly bags, and reusable fabric totes are sustainable options. They reduce environmental impact compared to traditional plastic bags while meeting durability needs.